Porosity Analysis

The favorable properties of composite materials have made them very popular in recent years. Compared to conventional materials, fiber-reinforced plastics are extremely rigid, lightweight and have a low thermal conductivity. They are increasingly being used in the aerospace and automotive industries, where parts have to be extremely resistant to stress and be of a consistently high quality. Air inclusions, cracks and similar defects have a major impact on stability and the ability of a composite material to withstand stress. Such defects are therefore classified as critical if they occur in components that are relevant to safety.

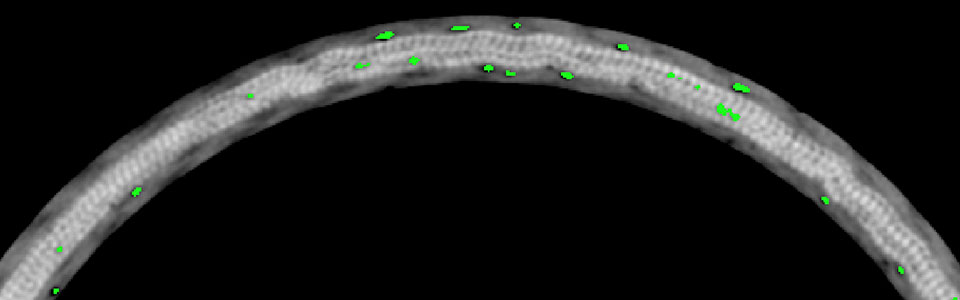

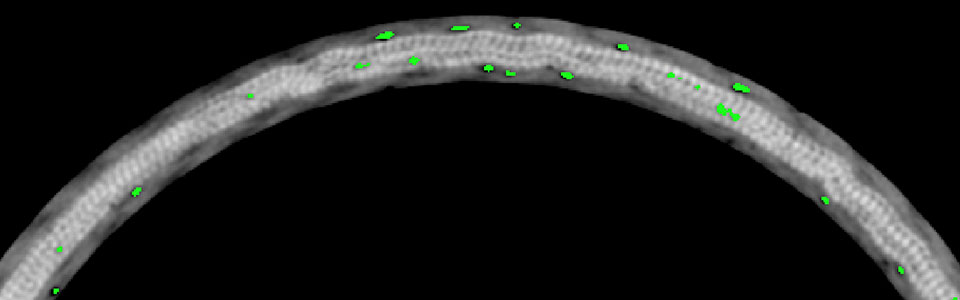

Industrial x-ray tomography is a non-destructive method used to generate and analyze volumetric models of materials. However, large amounts of data are also produced, which need to be evaluated efficiently and accurately. To speed up the process, an algorithm has been developed and implemented, which identifies pores from extrema in the gray-value distribution of voxels and quantifies them using a region-growing approach.

Compared to commercially-available algorithms, this approach has a higher search speed and the pores found are of a better quality. Furthermore, statistics on pore density, distribution, size and volume can be compiled, thus enabling components to be reliably assessed for the presence of pores.