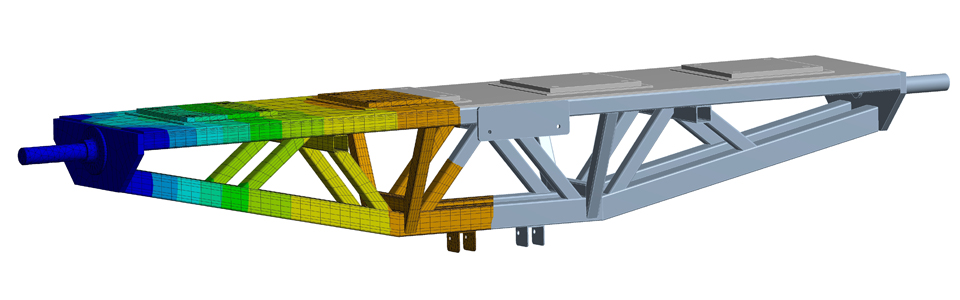

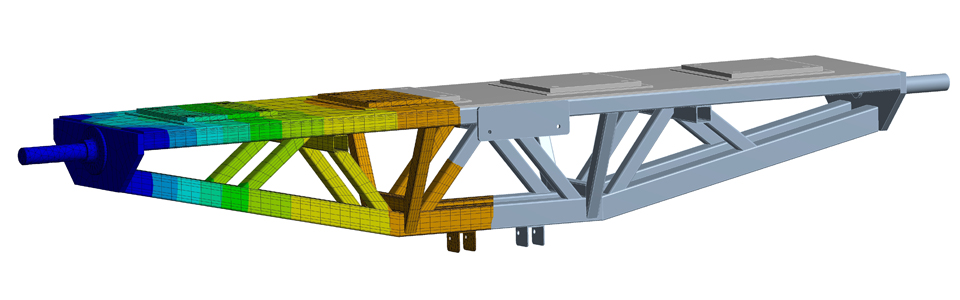

FEM-Simulation

Current demands to improve dynamics and energy efficiency as well as to reduce material consumption make lightweight construction technologies an interesting option for numerous applications in manufacturing and assembly systems. The paramount aim when developing lightweight solutions is to minimize weight while maintaining or even improving component robustness and rigidity. In the product development process, computer-aided calculation methods help to maximize the potentials of lightweight constructions. The methods are indispensable when it comes to developing innovative and future-proof design solutions. One of these methods is the Finite Element Method (FEM), which is used for calculations based on a CAD model.

The Department of Lightweight Construction Technologies implements ANSYS® - one of the most popular FEM software products for solving structural issues - to assess the rigidity and robustness of components or even complete subassemblies. Complex loads as well as a wide range of constraints can be modeled, resulting in much more detailed results than those possible with manual analytical calculations, for example. The software recognizes and prevents over-dimensioning and also identifies and optimizes critical areas, thus improving the overall design. To optimize the weight and robustness of structures, we also implement special add-on tools which enable us to incorporate lightweight concepts in the design process.