Lightweight Construction Technologies

Today, energy and resource efficiency are key issues in manufacturing engineering. The Department of Lightweight Construction Technologies at the Fraunhofer Institute of Manufacturing Engineering and Automation IPA develops innovative solutions to overcome these challenges.

The target of decreasing weight in automotive and aircraft construction is well known. However, in the future the quantities of materials used to manufacture consumer and investment goods also need to be reduced. This will not only cut production, transport and disposal costs but also help to alleviate the problem of resource shortages in the global market.

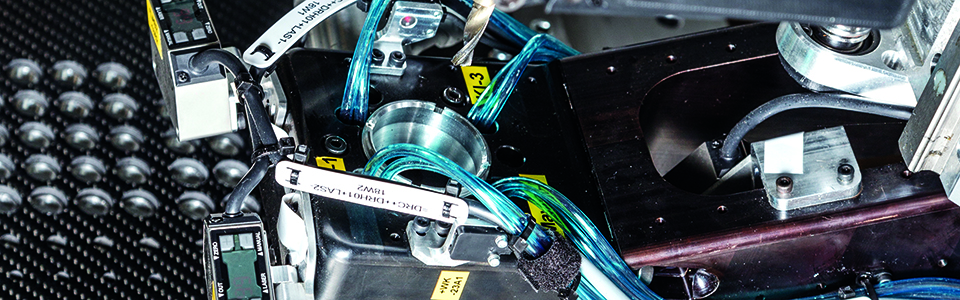

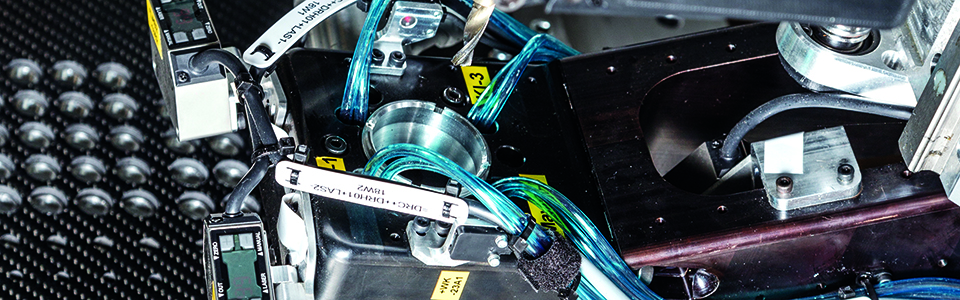

By implementing lightweight concepts and lightweight materials, such as carbon fiber reinforced plastic (CFRP), our customers need less energy to operate their machinery and lower their emissions at the same time. We also help them to implement lightweight concepts tailored to their requirements as well as use new materials to improve the performance of machines and equipment.