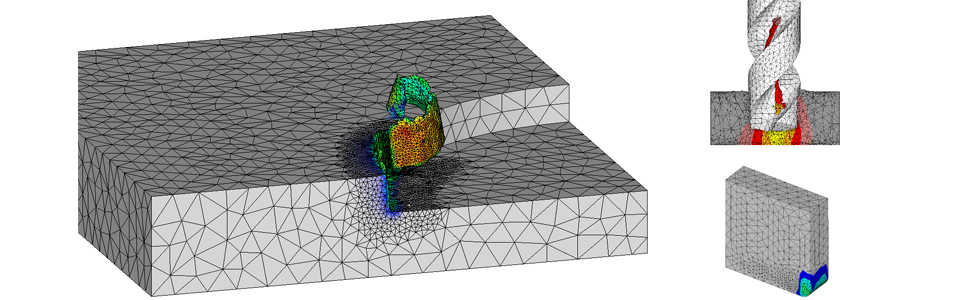

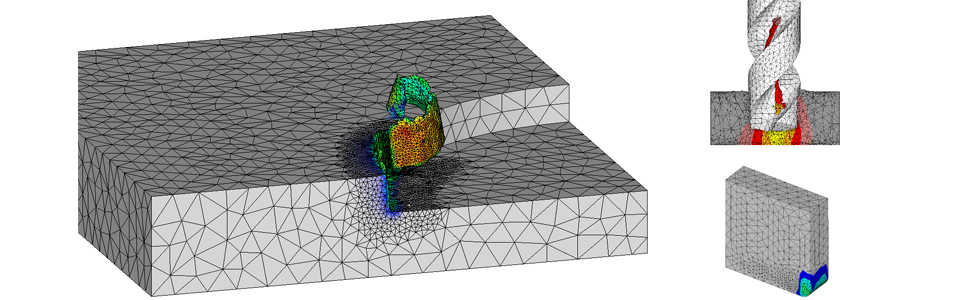

Simulation of Machining Processes

Modern lightweight construction technologies call for in-depth understanding of the mechanical behavior of single materials and composites. Simulation technologies allow the various properties of materials in the form of composites to be studied.

The complex properties of lightweight structures place great demands on manufacturing processes. Simulation is an indispensable aid when it comes to analyzing the complex behavior of materials subjected to high process stresses. It is used to aid tool design and determine parameters for machining processes. As a result, the time and costs involved in developing new tools can be significantly reduced.

Our extensive experience in machining technologies and state-of-the art hardware and software enable us to simulate your machining processes exactly. We also generate material models to simulate machining processes on existing and future material structures.

Services:

- High-resolution simulation of machining processes

- Analysis of tool and cutting edge geometries and process parameters

- Analysis of the effects of residual stress and process temperatures

- Validation of simulations via experimental machining tests

- Test platform for process adaptation and tool development

- Generation of material models for simulations