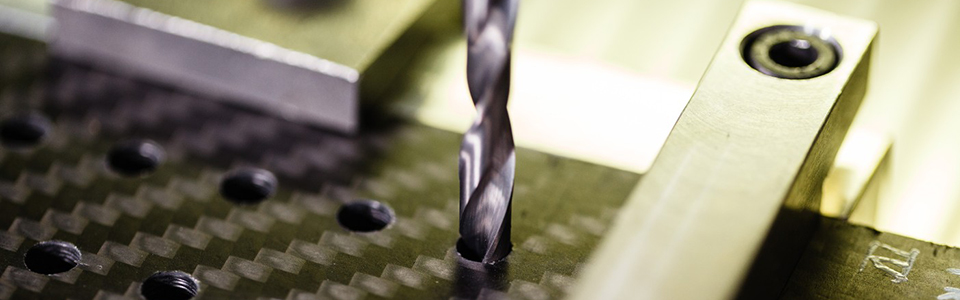

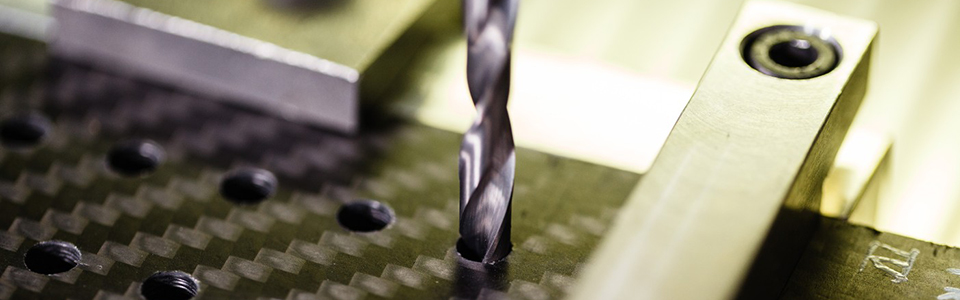

Machining and Cutting Technologies

To benefit economically from the promising potentials of lightweight construction in high-volume productions, processing costs for lightweight materials need to be cut significantly. Machining technologies and processes require improvement and modification because lightweight materials are processed in a different way from conventional metals. Examples of lightweight materials include fiber-reinforced plastics, such as CFRP and GRP, aluminium and titanium alloys, and also stack materials and composites.

The damage mechanisms affecting these materials and the requirements of tools, machine technologies and machining processes differ considerably. As a result, now and in the future, new concepts need to be developed along the complete machining process chain in order to realize cost-effective solutions for processing materials.

That is why the Department of Lightweight Construction Technologies at Fraunhofer IPA develops special machining and cutting technologies for these relatively new materials. In addition to machining processes and tool design, the department also focuses on coating technologies for tools, the implementation of cooling and lubrication systems as well as on simulating machining and cutting processes. Other key areas include the use of industrial robots in machining processes as well as ultrasonic-assisted cutting.