Ultrasonic-Assisted Machining

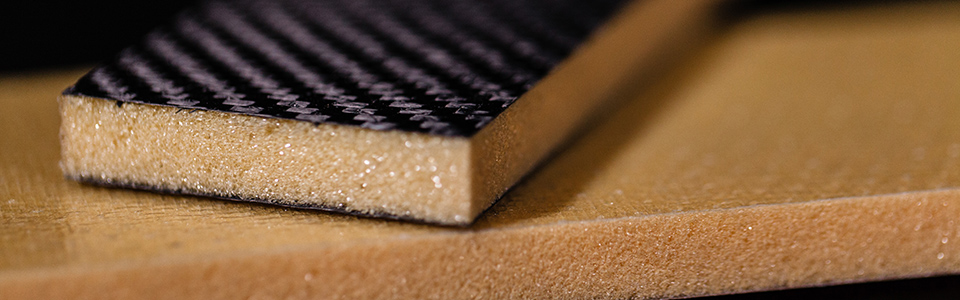

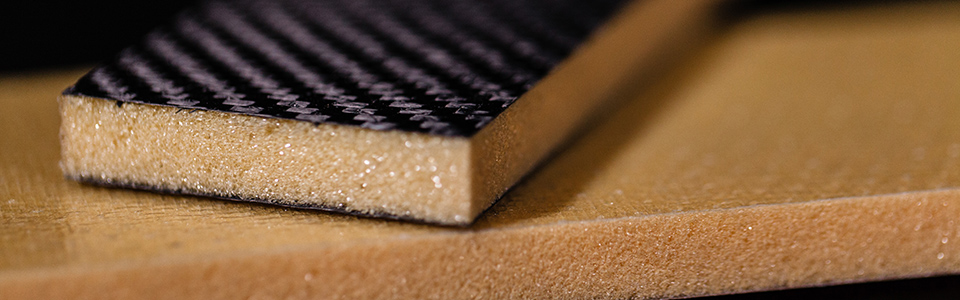

Ultrasonic machining is based on the introduction of added energy in the form of (structure-borne) oscillation. Relatively low amplitudes (approx. 10 µm) and high frequencies (approx. 20 to 60 kHz) are used. This combination enables extremely hard materials, such as ceramic composites, to be processed cost-effectively. It also improves the separating behavior of fiber composites, reduces process forces and enhances the quality of cuts made into materials that are very sensitive to pressure, such as foams or sandwich structures.

In cooperation with the Institute for Machine Tools at the University of Stuttgart (IfW), Fraunhofer IPA conducts research into the application of ultrasonics for processing a wide range of materials. It also develops components for diverse machining processes. A further research field of the Department of Lightweight Construction Technologies at Fraunhofer IPA is ultrasonic, chip-free, separating processes as well as joining and testing technologies. We specialize in designing machining processes and tools as well as in developing machine components to generate oscillations