Quick Check Order Management

Plan your production and supply chain better in future and control it more effectively!

Would your company like to redesign, improve or restructure its order management? Are you aware of general weak points in your order management but not entirely sure about the best procedure, the exact objectives and the factors to be considered? Would you like your improvement projects to be based on a structured analysis?

With our so-called »Quick Check Order Management«, potential for improving your order management can be analyzed quickly and efficiently. The Quick Check specifically uncovers the root causes of weaknesses in today's planning and control processes and uses them to derive fields of action so that you can improve your company's internal production planning and control (PPC) and/or cross-company supply chain management (SCM). We analyze the current situation qualitatively together with supervisors of key areas and experts, supplementing the analysis with available company key figures.

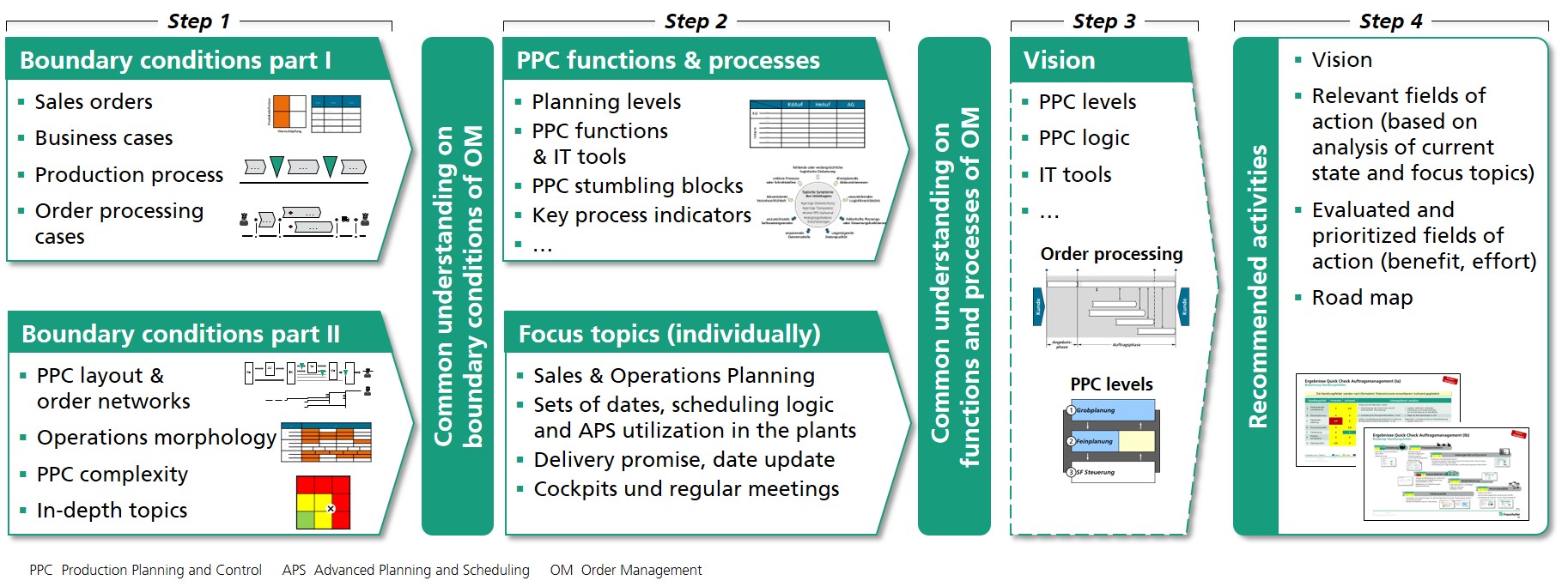

The Quick Check procedure comprises four steps

Step 1 identifies the general order management conditions in a structured manner. The goal is a common understanding of order processing from »customer to customer«, of manufacturing processes, as well as of business and processing scenarios. To analyze the status quo, two central visualizations are used: the order management layout and the order network. These visualize the boundary conditions of manufacturing (from engineering to distribution) and the product structure in a simple and easily comprehensible way. The so-called “operational morphology” helps by collecting further r boundary conditions. The results of these analyses represent the requirements for order management.

Step 2 aims to achieve a common understanding of the order management functions and focal areas. In this step, the current situation is analyzed, with a focus on the planning and control functions, their IT support, and their logical inconsistencies and gaps (so-called PPS stumbling blocks). If necessary, the planning and control processes, scheduling structure and spheres of responsibility can also be studied in more detail. Additionally, so-called “focus topics” are closely examined. Typical topics include program planning (S&OP), scheduling logic and capacity planning, and user-oriented cockpits (for preparing decision-making information).

Step 3 formulates a general vision of the intended future of order management. This vision is based on the specific order management requirements developed in Step 1 as well as on the analysis of the status quo of order management functions and focal areas.

Step 4 derives the measures required to achieve the vision, using best practices as guidelines. The participants evaluate these measures in terms of potential and the respective effort required to exploit it. Last but not least, the results are aggregated into a road map.

Quick Check Order Management identifies the strengths and weaknesses of planning and control processes in internal order processing and supply chain management in a structured manner, including relevant software tools. From this, initial solutions or fields of action for improvement are derived.

Fraunhofer IPA’s Quick Check Order Management offers you the following benefits:

- Common understanding of strengths and weaknesses in order management

- Identification of key fields of action

- Clear idea of goals and how to achieve them

- Better planning and more effective control of your production and supply chain

Quick Check Order Management is thus aimed at all companies (especially SMEs) that want to take a closer look at both their internal PPC and inter-company SCM.