Reorganizing and Optimizing of Maintenance

Does your maintenance follow a strategy aligned to the overall optimum? Do you know and exploit all potentials of your maintenance?

Maintenance management has the difficult task of developing strategies and measures to ensure machine availability while simultaneously taking aspects such as costs, product quality, safety, value conservation and environmental protection into account.

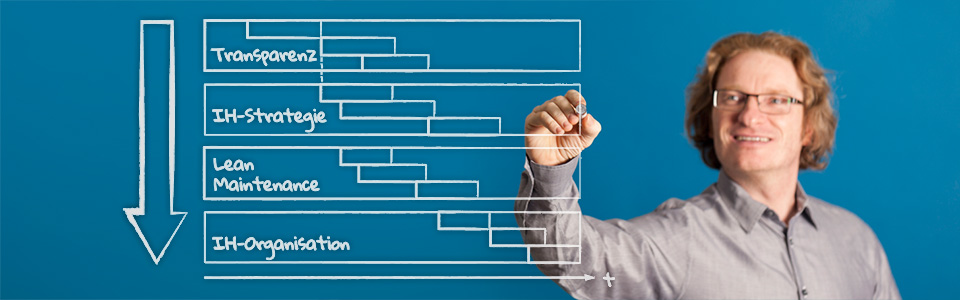

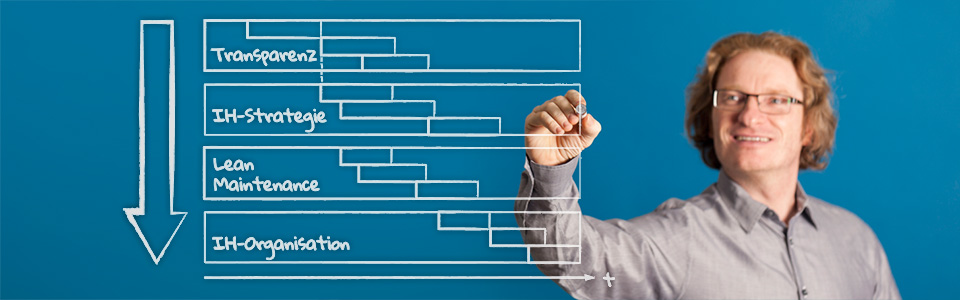

The experts at Fraunhofer IPA support you throughout the entire planning and optimizing maintenance strategy process – from analysis through conception to implementation. On the basis of the analysis of the current situation a holistic concept is developed to unleash the full potentials of your maintenance.

Therefore the following critical success factors are taken into consideration:

- Transparency regarding costs and performance

- Maintenance strategy geared towards production requirements

- Total productive maintenance concepts (TPM)

- Lean maintenance – wastage and loss free processes and workflows

- Holistic cost analysis (direct maintenance costs and failure costs)

- Risk-based maintenance strategy (focus on machine availability)

- Continuous improvement process (CIP) for maintenance

- Demand-orientated sourcing strategy for spare parts

- Holistic and effectiveness based maintenance controlling

- Efficient usage of Computerized Maintenance Management Systems (CMMS)