Vacuum Tribology

Friction causes wear – particulate contamination in high vacuum systems is a decisive factor when it comes to key high-tech areas because the damage potential is considerable. Such areas include the manufacture of chips and displays, photovoltaic products, optics, elementary particle research and aerospace. In order to ensure efficiency (low reject rates) and operational reliability, being able to control the sources of particles is essential. Despite this, up till now very little research has been conducted on the complex interrelationships between tribological conditions, tribological stress, wear, particle generation, particle release and particle spread in a high vacuum environment, which in this order can cause severe damage.

Due to major differences between a high vacuum and atmospheric conditions, current knowledge and optimization approaches cannot be transferred to a high vacuum environment. These include:

- Absence of moisture films on surfaces

- No formation of new oxide layers

- Low number of residual gas particles

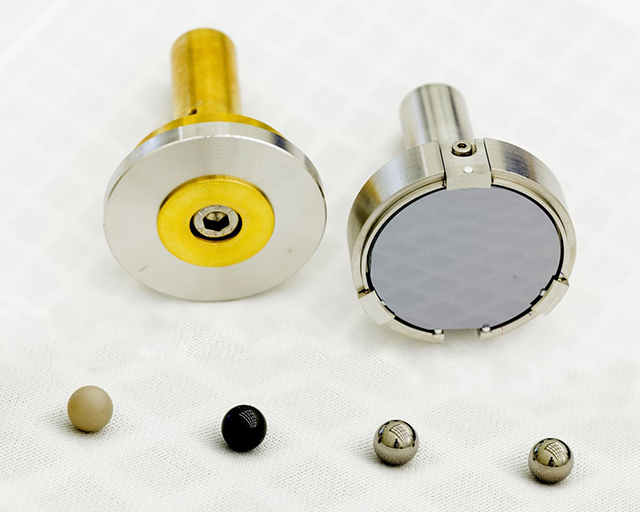

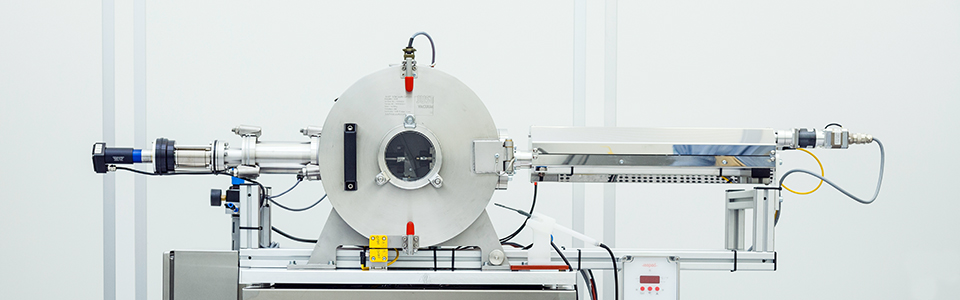

To close this research gap, a new method has been developed at Fraunhofer IPA. The process comprises a new high-vacuum tribometer with localized detection and measurement of released particles, as well as a methodology for evaluating wear and the emission and spread of particles. The high vacuum tribometer allows defined stress to be applied to different model and real tribosystems during sliding and impact movements, combinations thereof, and also rolling movements. In addition, the temperature of the counterbody, the vacuum pressure and electrostatic fields can be adjusted. A directional filter can be used to determine the distribution of particle emission velocity. The methodology encompasses the effective planning and execution of experiments, including statistical design of experiments (DOE) to determine the complex relationships between the parameters set on the vacuum tribometer and newly introduced cleanliness-related target variables (evaluation variables). Target variables for particle emission are the total number, size, size distribution, total volume and emission rate of particles. Key target variables for particle spread include the velocity and direction of emission, as well as the size-dependent and spatial distribution of particles in relation to distance from the tribosystem.