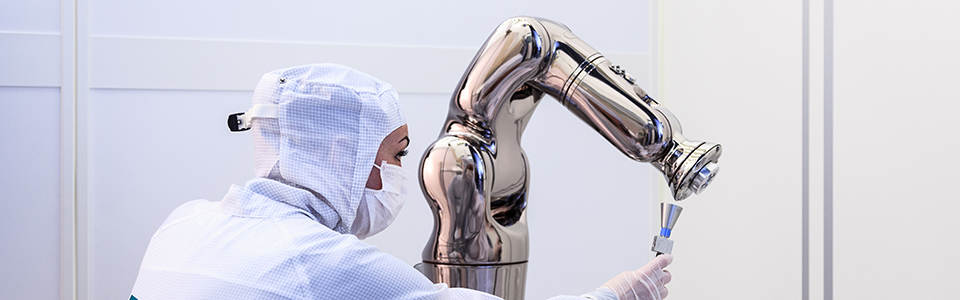

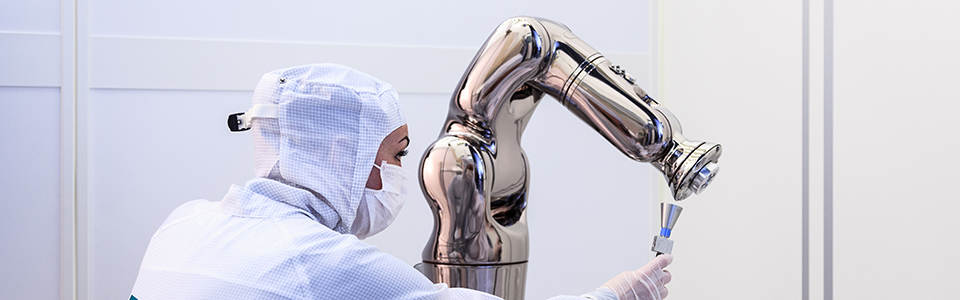

Cleanliness-Suitable Equipment and Components

Even the smallest contamination can have a damaging effect in production under clean conditions. Particulate, layered, microbiological or even molecular contaminants impair product quality and functionality to such an extent that high reject rates and quality losses can occur without suitable measures. For this reason, it is important to consider factors relevant to cleanliness when planning, setting up and operating a production facility and to consistently implement the cleanliness aspects.