Chemical Cleanliness

In industries with high cleanliness requirements, such as aerospace, medical technology or semiconductor and automotive industries, monitoring chemical cleanliness is increasingly important. Even the smallest amounts of contaminants can lead to anything from impairment of product quality and safety to malfunction. In addition to monitoring contamination-critical process steps, Fraunhofer IPA offers problem-oriented solutions for individual and customer-specific applications with high cleanliness requirements.

Tabbed contents

Components and surfaces

Chemical cleanliness on components and surfaces

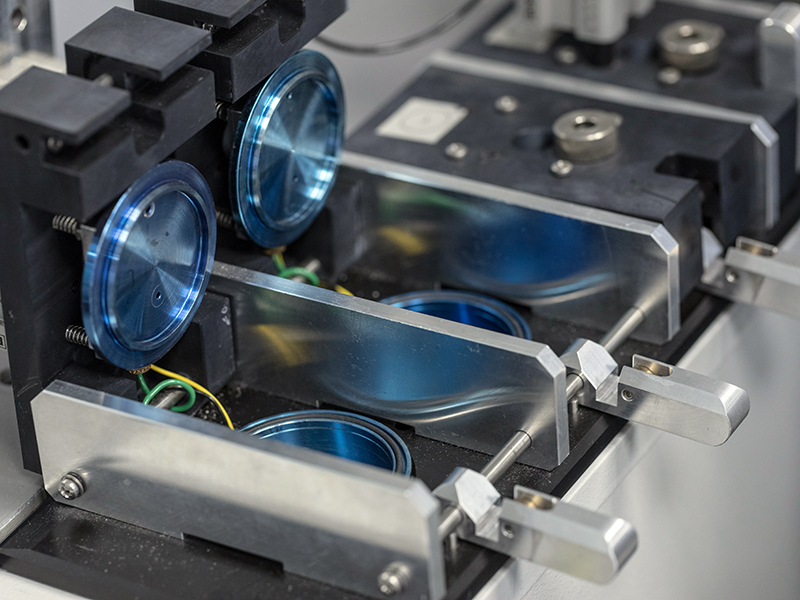

While in many applications a defined level of contamination on components and surfaces is desirable (e.g. in corrosion protection), in conventional process steps such as bonding, coating and welding, even the smallest contaminations can have serious consequences for the functionality or downstream processes. Continuous monitoring of the chemical cleanliness status is therefore an important part of quality control.

Whether organic and inorganic contaminations on technical surfaces, time-dependent haze effects on optics, outgassing and long-term storage effects of materials or contact transfer – we support and provide advice on the cause analysis and evaluation of chemical cleanliness on components and surfaces of any kind.

We can offer a wide range of methods and equipment for individual applications:

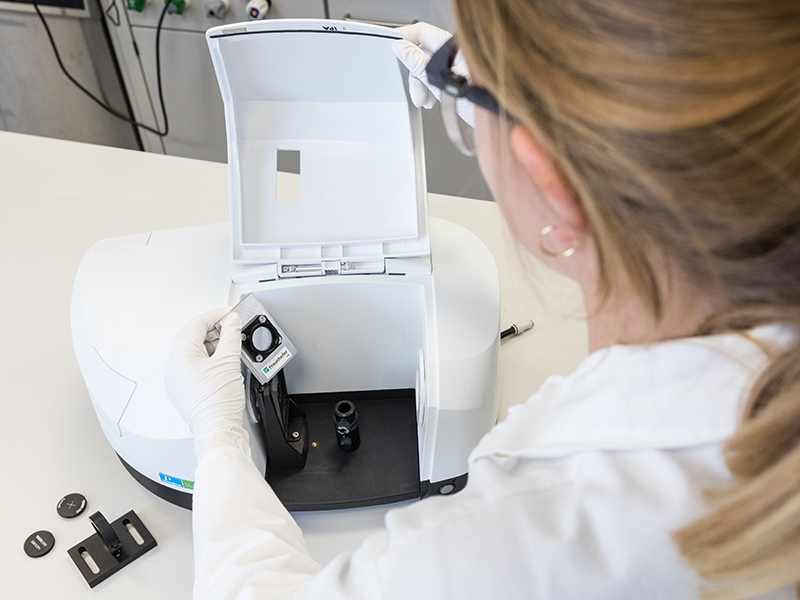

- Extraction method with ultraclean solvent for ultra-trace analysis by means of FTIR spectrometer

- Minimal amount extraction and determination of non-evaporable residues (NVR)

- Cleanliness and outgassing testing of materials/components with thermal extraction chambers up to 300 °C from 0.001 L to 200 L

- Ultra-trace analysis in the ppt range using ion chromatography (IC)

- Methods for monitoring condensable substances during production (e.g. in aerospace)

- Portable instruments (fluorescence, contact angle measurements to determine surface free energy, etc.)

- Total organic carbon (TOC) as sum value of organic contaminations

Air and gases

Chemical cleanliness in air and gases

With the increasing cleanliness requirements, the monitoring of the process environment in contamination-critical areas is also constantly increasing. Depending on the process, predefined limit values must not be exceeded in order to meet product-specific cleanliness requirements. Often, for example, solvent-based adhesives, coatings, materials or flooring systems unknowingly introduce chemical contaminants into process environments. In many industries, these unwanted components in the air can lead to defective products, production downtime or even damage to health.

Fraunhofer IPA provides a variety of methods for the reliable monitoring of a chemically clean process environment:

- Ultra-trace analysis of airborne organic contaminants (VOC/SVOC) by thermodesorption gas chromatography-mass spectrometry (TD-GC/MS) using different adsorber systems (Tenax®, Carbotrap, molecular sieves, etc.).

- Gas and air sampling with traps and impingers

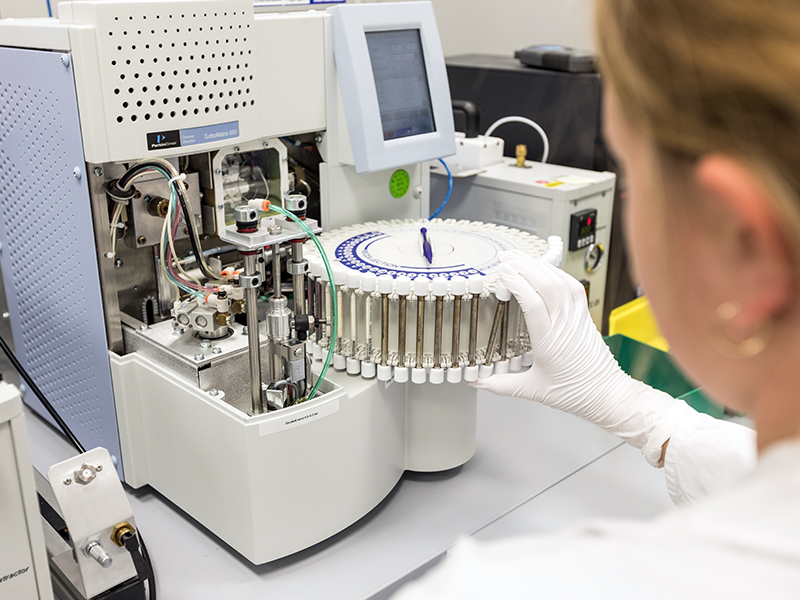

- Ion chromatography for ultra-trace analysis of anions and cations, inorganic acids as well as ammonia in the ppt range

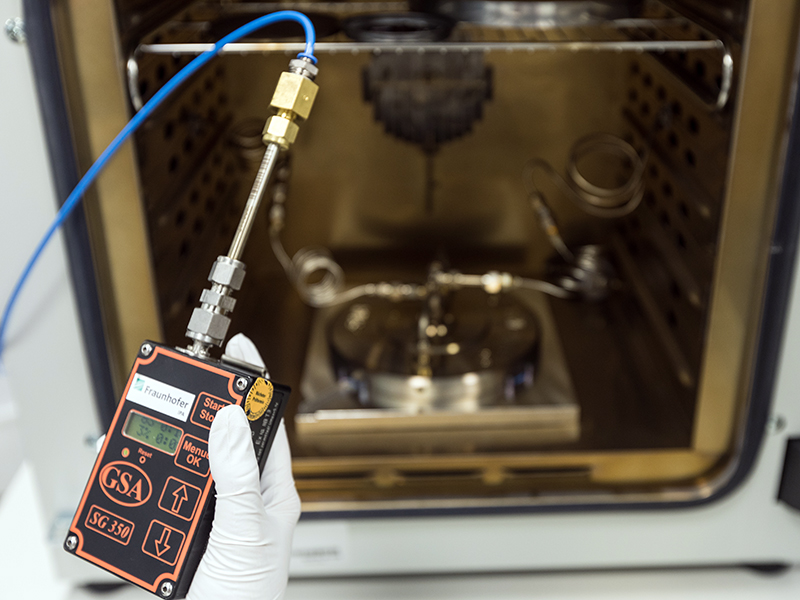

- Outgassing testing of materials or components with emission cells and chambers from 10 cm3 to 1 m3

- Cleanliness and outgassing testing of materials/components with thermal extraction chambers up to 300 °C from 0.001 L to 200 L

- Method for selective measurement of condensable substances

- Portable devices (e.g. ppb PID detector, ozone, selected gases, etc.)

Liquids

Determination of chemical contamination by liquid extraction

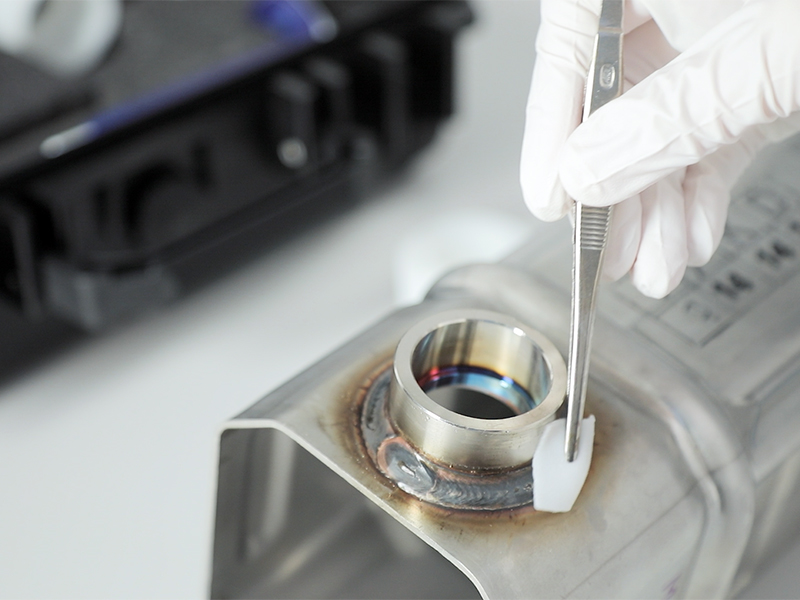

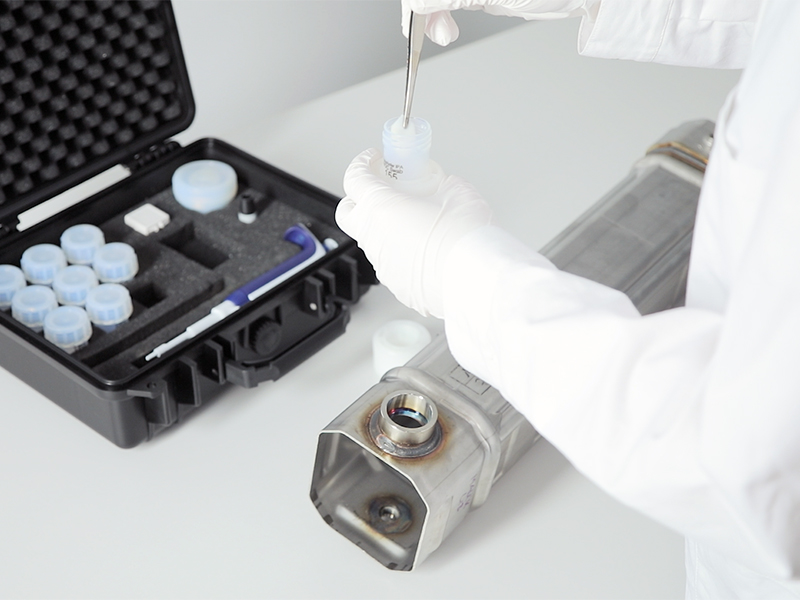

The determination of chemical contamination – whether airborne or condensed on surfaces – by liquid extraction is becoming increasingly important. When transferring the contaminants into ultra-clean liquids, geometric factors (small/large surface area, internal or structurally difficult-to-access locations) often play a major role and require component-specific extraction methods.

Depending on the type of contamination, the following methods can be used:

- Liquid extraction method using components of any kind with ultra clean solvent for ultratrace analysis by FTIR.

- Quantitative ultratrace analysis in the ppt range of anions and cations, inorganic acids as well as ammonia in ultraclean water using ion chromatography (IC)

- Riboflavin solvent extraction and ultra performance liquid chromatography (UPLC) using different detectors (ELSD, UV)

- Minimum volume extraction and determination of non-evaporable residues (NVR)

- Conductivity determination as sum value of ionic contaminations

- Total organic carbon (TOC) determination as sum value of organic contaminations

Medical devices

Cleanliness of medical devices

By law, medical technology companies are liable for their products. They are obliged to minimize the risks for patients if their products are used as intended. Fraunhofer IPA offers a wide range of services on this subject.

Further information can be found here.

Test methods and systems

Development of test methods and systems

The analysis of contaminations – whether on surfaces, in the air or in liquids – is now possible with a variety of methods and devices. With increasing cleanliness requirements in the industries, the demand to meet them is also rising. Often, test methods and systems need to be adapted or newly developed to suit the specific product application. Many companies are faced with the question of what is necessary to achieve the required product quality.

Fraunhofer IPA provides a wide range of suitable methods and laboratory analytical procedures for detecting a wide variety of contaminations.

We gladly support you in the development and optimization of your individual and component-adapted test method. Optionally, the test method can be integrated into an (existing) system.

Guidelines

Guidelines

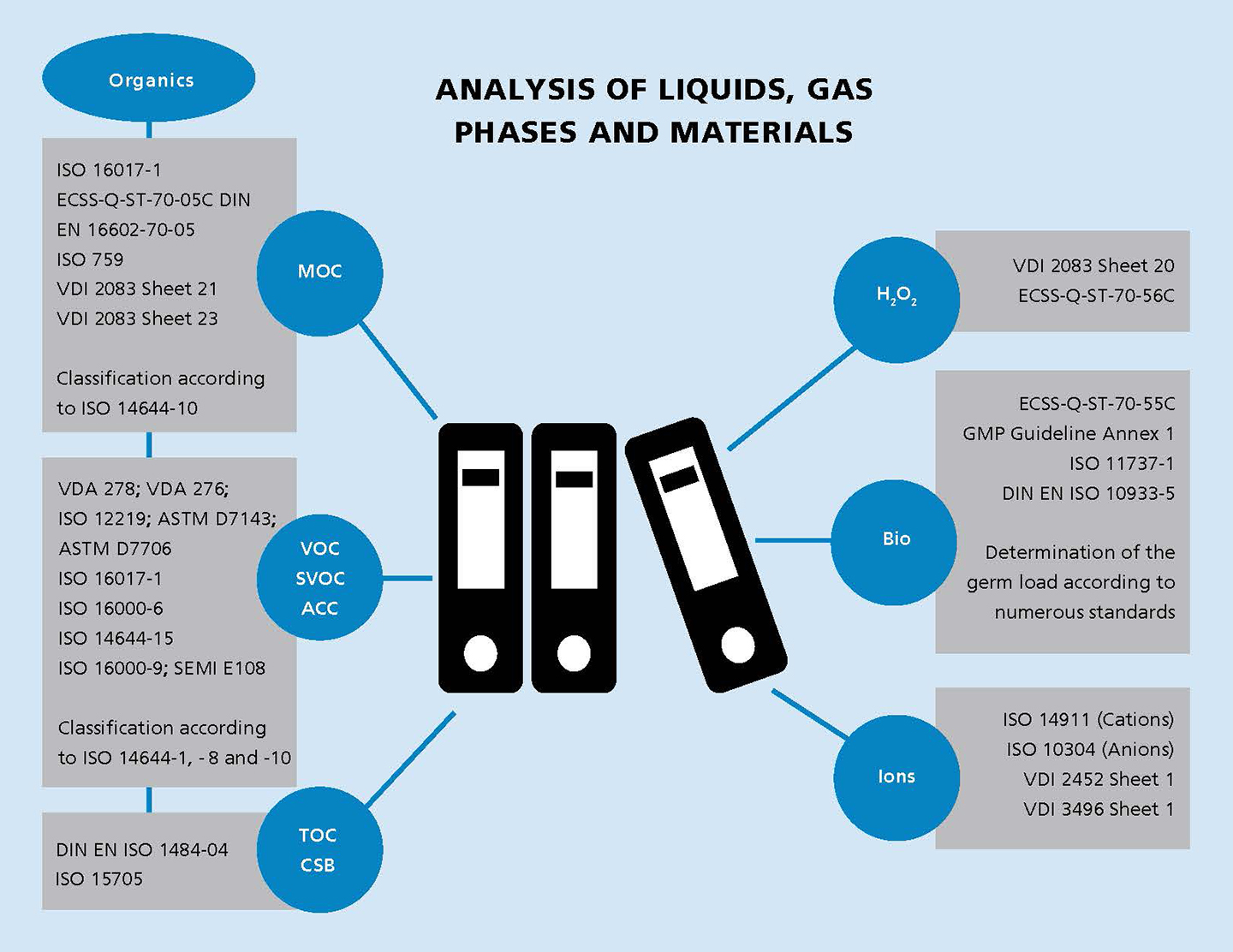

We perform standardized analyses according to national and international standards. The illustration shows an extract of the applied standards in the field of analysis of liquids, gas phases and materials. Further standards are also applicable and can additionally be implemented on a customer-specific basis.