Key areas

Most of the work carried out at Fraunhofer IPA concerns important aspects governing the manufacture of electronic products and microsystems along the entire value chain. These range from production-oriented product design and suitable materials, through the challenges faced by processes and machines due to rising miniaturization levels, right up to searching for ways to achieve and assure the high quality required.

Materials and surface engineering

Right from the start of product development, we give manufacturers of electronic products and microsystems the assistance they need. We help you to assess and choose materials so that you can design an individual product with integrated functions. Regardless of whether it is a high-performance protective coating for a surface or an electrically-conductive ink for applied conductive layers that you need.

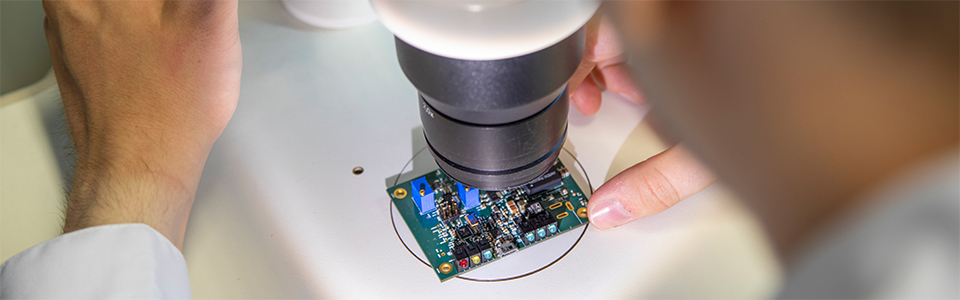

Process and systems engineering

To meet the high levels of precision and reliability required, we develop processes and systems tailored to your needs, e.g. for surface processing and surface cleaning, assembly and integration, as well as for quality assurance and control. We develop individual as well as general solutions, each with the appropriate degree of automation. The spectrum ranges from manual workplaces for producing small series of optical and mechatronic aggregates, through semi-automated systems for medium-sized lots, right up to linked lines for mass production. With our processes, we cover important production steps that have an impact on quality in the fields of pretreatment, assembly and quality control. We are also breaking new ground when it comes to manufacturing innovative products, e.g. by combining 3-D printing methods with integration technologies derived from assembly processes to develop a hybrid solution.

Production and cleanroom conditions

The cleanliness requirements of electrical and microtechnical components and products are increasing. With our many years of expertise in cleanliness technology, we support you in the planning and designing your clean production environment in accordance to your needs. Our supplementary services cover anything from ultra-trace analysis, through certifying operating utilities from the aspect of cleanliness, to offering training courses for staff working in clean zones and cleanrooms.

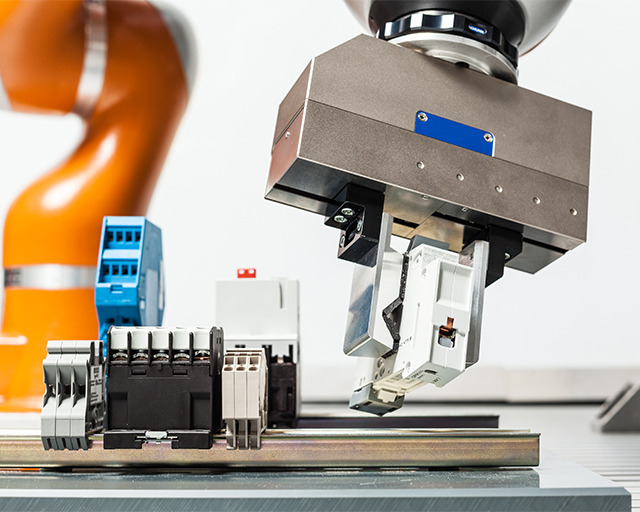

Robotics and automation

We develop robots and automation solutions for industrial applications and for the service sector. You benefit from the conception to the implementation of innovative industrial robots, service robots and intelligent machines - both as a (future) user and as a system integrator or component manufacturer.

Benefits of artificial intelligence

Production and quality data can be evaluated and interpreted by means of artificial intelligence. AI also enables autonomous planning and decision-making for processes, with application for example in process automation and optimisation, quality assurance and production control. We support you from feasibility studies to the implementation in the production process.

Analysis, planning and optimisation

In addition, we are happy to give you advice on analyzing and assessing technical feasibilities and potentials during product development and implementation, as well as helping you to plan and optimize your planned or existing production facilities.