Matrix production in flow at the Siemens AG plant in Karlsruhe

In Short

The decision to implement a new plant strategy at Siemens in Karlsruhe has brought about higher production demands. To meet these requirements, the decision was made to introduce matrix production combined with classic lean lines. The measures needed for implementation were analyzed together with an interdisciplinary team from Fraunhofer IPA.

In Detail

One of Siemens’ largest factories in Germany, the Siemens AG plant in Karlsruhe manufactures products and solutions in the fields of electrification, automation and digitalization. The Siemens plant in Karlsruhe has decided on a new - hybrid - production strategy. On the one hand, the strategy pursues the goal of using firmly interlinked and clocked lines based on lean principles wherever possible. On the other hand, it also allows a matrix concept to be implemented wherever high variance is required. In this respect, the Karlsruhe plant occupies a pioneering position among Siemens’ factories.

To take into account the latest developments in manufacturing engineering, support from a research institute was considered beneficial. For this reason, an interdisciplinary team from Fraunhofer IPA (Department of Factory Planning and Production Management, Department of DigITools for Manufacturing and Department of Robotics and Assistive Systems) was commissioned to examine the development steps required to implement the matrix strategy.

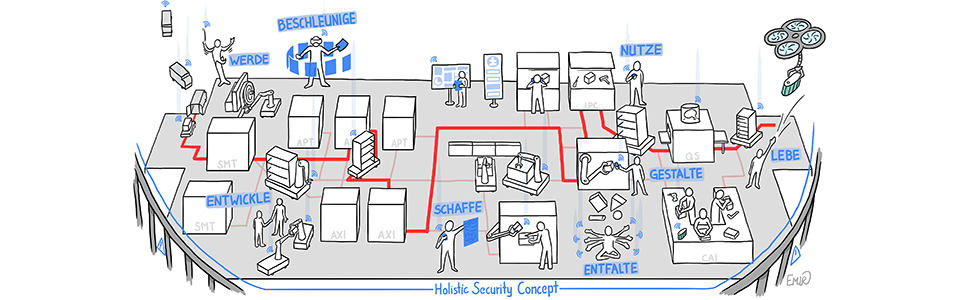

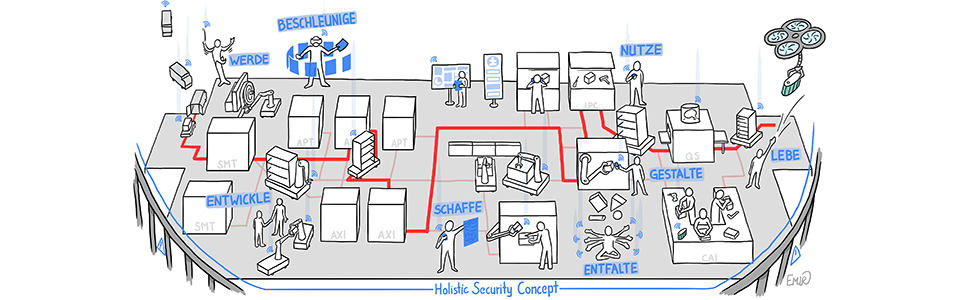

In various work packages, all areas of manufacturing management, such as production planning and control, IT architecture, logistics, manufacturing and assembly, were analyzed to determine the requirements for introducing matrix production. Also, feasibility studies on automated material transport and the use of artificial intelligence were carried out.

Based on the results of the analysis, the IPA experts defined the target states and, together with those in charge of the divisions at Siemens, derived the necessary development steps. The results of the various work packages were presented in joint workshops and used to develop a vision. Finally, a roadmap that would enable the vision to be achieved was drawn up showing all the area-related development steps and their interdependencies.

This allowed to jointly create a definition of target states that was accepted across all divisions as well as to identify fields of action with concrete development steps for integrating the matrix production system.

In follow-up projects, work began immediately on the joint implementation of the development steps. Implementation is scheduled to be completed in approximately three years.

Insights into the project

“At the Siemens plant in Karlsruhe, we consciously asked ourselves how we can secure and further develop our future viability as an electronics factory in Germany by adopting an innovative and future-oriented production strategy. Fraunhofer IPA's interdisciplinary approach helped us to supplement the end-to-end analysis of our manufacturing operations - from PPS and IT architecture to logistics - with a valuable external perspective. In this way, we were able to jointly identify and define the necessary changes for all essential elements of production. The collaboration with the IPA team was characterized by comprehensive methodological expertise and a strong focus on application orientation.”

Manfred Kirchberger, Technical Plant Manager Siemens Manufacturing Karlsruhe