Electroplating Plants

We offer our customers wide-ranging support in planning, optimizing and developing electroplating production plants. Our interdisciplinary approach means that our engineers and designers bring extensive knowledge into plant planning, also about the electroplating processes themselves. However, if any unanswered process-related questions arise, we can clarify these via appropriate laboratory tests, because the best plant can only work with a process to match and vice versa! In addition to the typical production workhorses, rack and barrel plating lines, our technology portfolio also includes continous strip electroplating, plants for electroplating of large components, brush electroplating and selective electroplating.

Our range of services

This covers a broad spectrum, starting with feasibility studies and projects for improving plants in terms of capacity or quality, e.g. by optimizing layer thickness distributions, through to planning completely new plants, including the construction of prototypes for key components or special-purpose plants. We also provide support for strategic projects, such as those involving investment decisions, with the appropriate technical expertise.

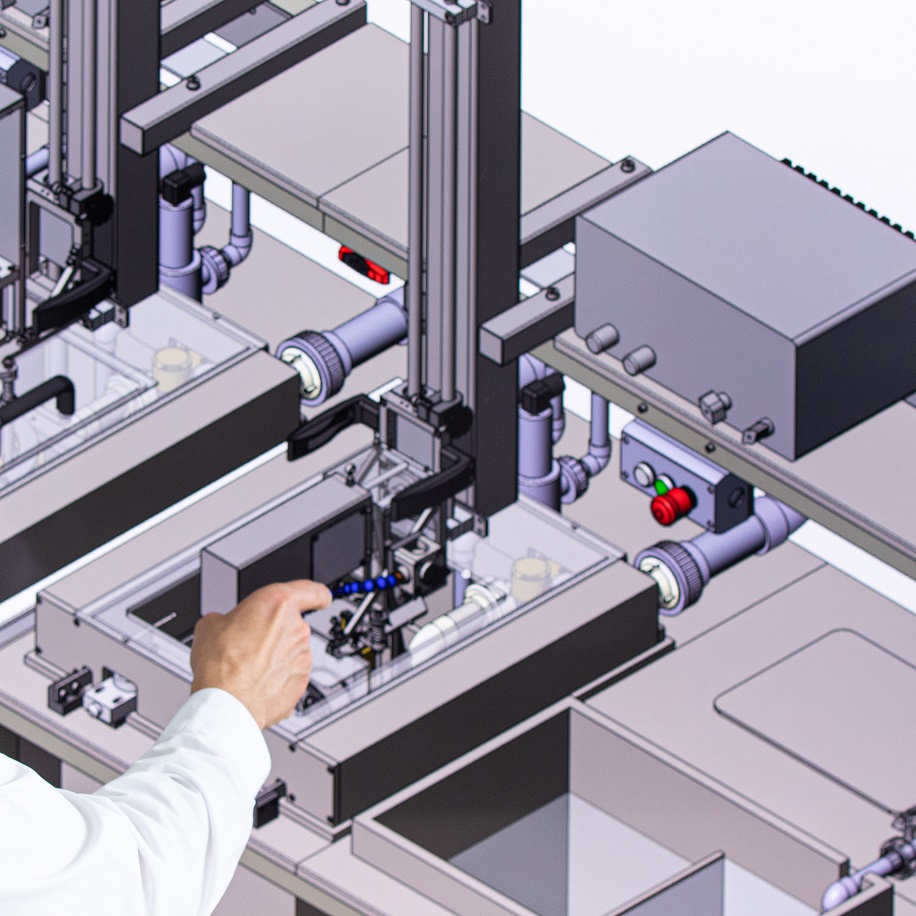

Prototype construction

Plant optimization

Electroplating plants are investment goods with a long service life. Optimizing them at regular intervals ensures consistently good results from both the technical and economical perspective. Thanks to our many years of experience in plant design combined with our in-depth knowledge of process technology and interactions with substrates, we develop long-lasting and future-proof solutions for our customers.

Special-purpose systems

Planning new electroplating plants

Only on rare occasions do companies have to plan completely new electroplating facilities and consequently tend to have little experience in tackling such challenges. We develop efficient technical solutions for our customers with well-designed layouts and systems. If desired, we provide support from the beginning of the project right through to commissioning the finished installation.