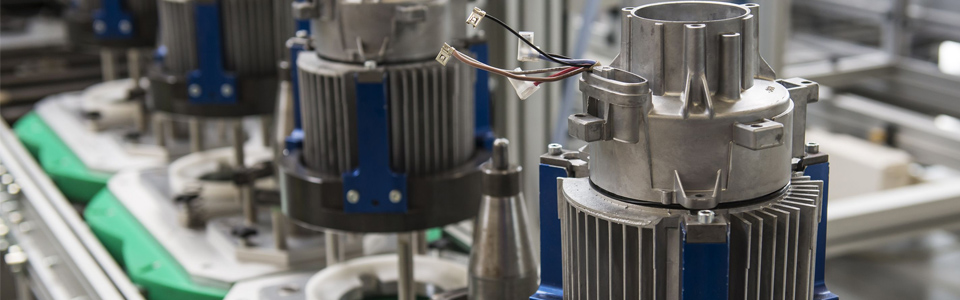

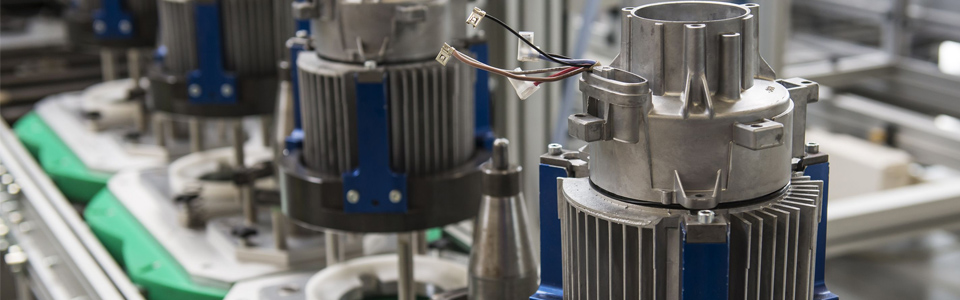

Product and Value Design

Product and value engineering, product functions and their impact on equipment investments

In many companies, product and value engineering is often characterized by outdated planning procedures: planning processes for manufacturing systems and equipment are often based on the assumption of an “unmanned production”. As a result, the focus is mainly on implementing technical processes and assuring their quality. It is extremely rare that a customer’s product requirements are taken into account. Investments in manufacturing systems and equipment are generally budgeted at overall system level and the amount of added value from each component is not taken into consideration. If an investment is made larger, existing plans are usually simply updated. This not only increases product complexity but also manufacturing complexity.

Here valuable savings can be made. Cost savings can be calculated using a method based on processes and values.

Services

As part of a joint project with you, we develop an adapted procedure for designing a value-based manufacturing system tailored to your requirements. We implement the following concepts:

- Alignment of the discrepancy in value between customer benefits and the process costs that are necessary to create the required functionality (based on the value analysis described in VDI Guideline 2800)

- Reduction in product complexity

- Evaluation of the distribution of investment costs (added value, logistics, quality assurance, basic costs, handling, etc.) and the degree of automation in the structure of the manufacturing system or equipment

- Inclusion of site-related cost structures and specific logistics costs

- Assessment of the potentials of “quick win” and “long term”

- System structurization taking value orientation, vertical integration and the future degree of automation into account

- Selection and evaluation of the technology

- Conception of scenarios under the application of customized design assumptions (e.g. low/ high cost of location, workshop/line capacity, robustness)

- Simulation of concepts at different levels

We provide you with support throughout the entire project – from setting goals through applying the method right up to implementation. If desired, at the end of the project we also compile a report of the results and recommend possible courses of action.