Sawing Technologies

Sawing technologies – found in almost every production chain – also play a major role when it comes to processing a wide range of materials. That is why the Department of Lightweight Construction Technologies at Fraunhofer IPA has set itself the target of implementing innovative technologies to further reduce cutting forces and noise levels. These technologies also enable thinner tools to be used and circular saws to be manufactured more cost-effectively.

Close networking of competencies and mutual collaboration with the Institute for Machine Tools at the University of Stuttgart (IfW) in the field of sawing technologies has led to foundation of the “Stuttgarter Kompetenzzentrum Sägen” (SKS). This partnership enables us to find solutions to industrial and research tasks quickly and efficiently. We address challenges concerned with sawing processes in the areas of machining, cutting, machine tooling and machine technologies.

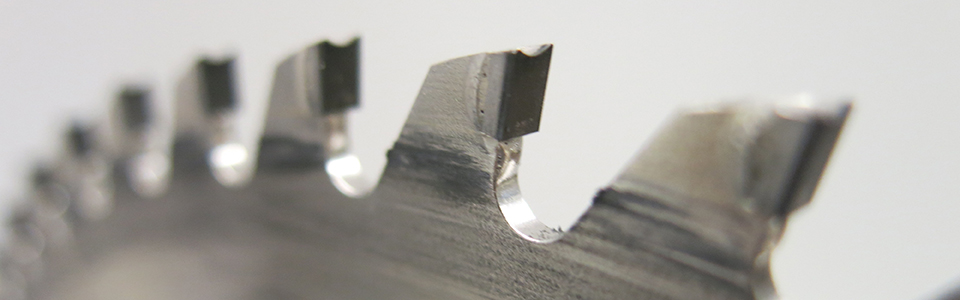

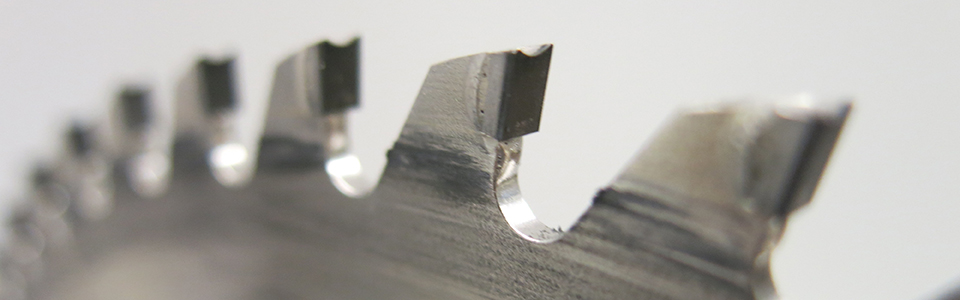

With our in-depth knowledge – from the saw tooth through extraction systems right up to safety– we offer our customers unparalleled process expertise. By taking a holistic approach and optimizing the overall situation, we not only improve aspects of a process but also consider their effects on other systems. Additionally, this serves to increase the global cost effectiveness of the separation process.