Assembly Processes and Tools

Requirements of assembly tools

When developing robot tools for assembly, the following requirements increasingly need to be taken into consideration:

- Intelligent sensors for inline process monitoring and control

- Remote intelligence to reduce process data transmission

- integrated bus systems to reduce wiring complexity

- “Plug-and-produce” design (quick and easy mechanical connection of tools to robots as well as independent log-on of tool controllers to robot controllers)

Services

Based on the latest scientific/technical methods, we develop for and with you the tool solution you need for your assembly task, including:

- Development of systematic solutions and selection of suitable technologies

- Tool development (prototype design and construction)

- Construction of robot pilot systems

- Determination and testing of alternative process strategies

Trends and technologies

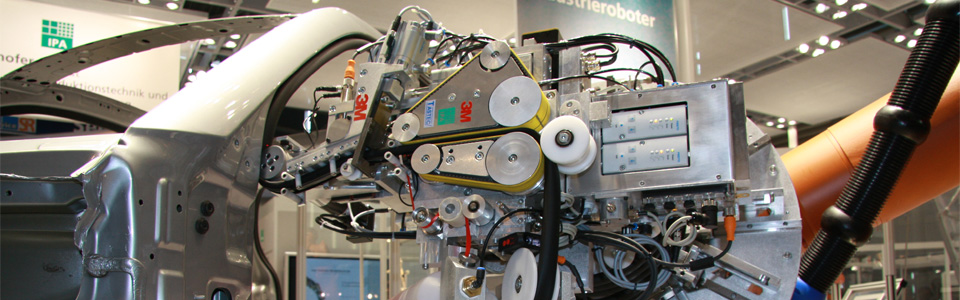

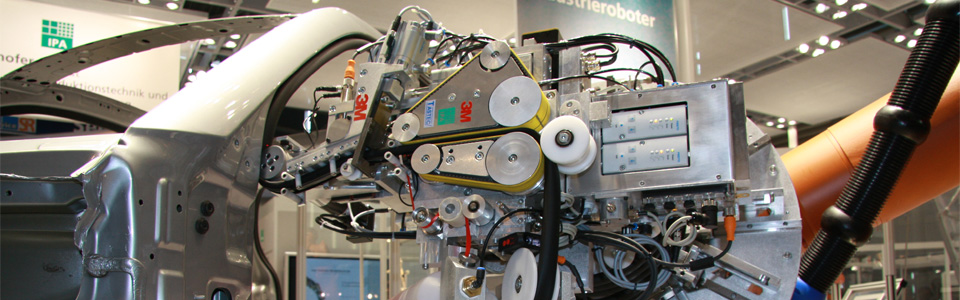

Current market developments focus on robot tools with integrated process monitoring and control, with tools being designed as “plug & produce” modules. The interface to the robot only needs a power supply, air supply and signal interface (e.g. Profibus). The process-specific sensor/actuator is connected directly to the tool controller, which functions independently of the robot.

Sample applications

- Sheet-metal joining technology (clinching, wobble clinching, punch riveting)

- Flexible parts (self-adhesive profile gaskets, cord-type gaskets, o-rings, etc.)

- For winding copper flat-wire packages onto coils for MRI scanners

Vollautomatische Applikation von selbstklebenden Türdichtungen mit Roboter