Assembly Automation

Tabbed contents

Expertise

We have gained a wealth of experience in planning and implementing industrial assembly systems and obtained results from numerous research projects on assembly automation with robot systems. We develop for you and in collaboration with you, fully-automated or partially-automated solutions tailored to your assembly requirements.

Services

- Identification of technically- and economically-feasible automation potentials in your assembly

- Development of innovative assembly processes and corresponding tools and systems for your assembly tasks

- Process assurance by means of feasibility studies in our optimally-equipped assembly laboratory

- Design of partially- and fully-automated assembly lines for your products, taking your specific general requirements into account

- Development of software solutions for controlling assembly processes and analyzing the necessary sensor data

Technologies and innovations

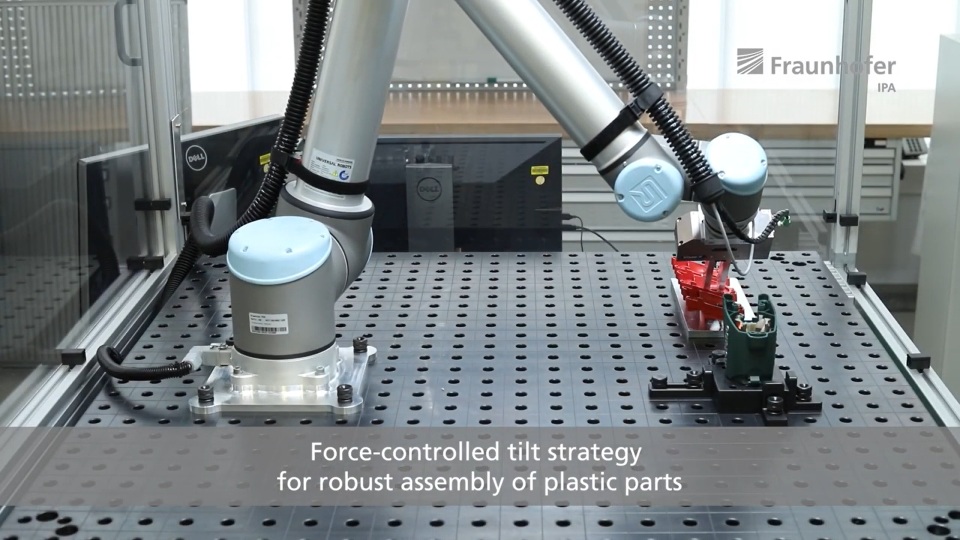

- Sensor-controlled joining processes using force-torque sensors and 2D and 3D cameras

- Safety concepts and interaction concepts for assistive robots to enable human-robot collaboration

- Programming methods and user interfaces for intuitively programming assembly tasks

- Assembly of flexible components

Advantages

- Lower costs through automation

- Reproducible high quality

- Increased manufacturing capacity

- Enhanced ergonomics through reduction of physical stress on workers

Videos

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyAutomated assembly of mounting rails with »pitasc«

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyFlexible assembly process with pitasc

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyAutomation Potential Analysis-App (APA-App)

Assistive robot for riveting operations

Vollautomatische Applikation von selbstklebenden Türdichtungen mit Roboter

Konzeptstudie zur Mensch-Roboter-Kooperation zur Applikation einer selbstklebenden Türdichtung

Sichere Mensch-Roboter-Kooperation in der Montage

SMErobotics Trailer Video

Nieten, schrauben, klipsen: Viele Anwendungen. Eine Lösung.

INSITU – Intuitive und sichere Bedienung und Steuerung von Roboterassistenten