Cooperation in ecosystems

It is becoming increasingly difficult for companies to innovate on their own. And “reinventing the wheel over and over again” involves a lot of resources when it comes to developing software and implementing or refitting robotic solutions. “Isolated” solutions, which have often been widespread up to now, are detrimental to economic efficiency and prevent companies with small production facilities in particular from relying more on automation.

Ecosystems, which are partly also based on open source software, therefore make it possible to create partner networks in which all participants can jointly develop and offer innovations. Ecosystems also offer the opportunity to use a digital marketplace that ensures transparency of the products and services on offer. In this way, new customers can be acquired, and new digital business models can be developed and implemented.

ROS-Industrial

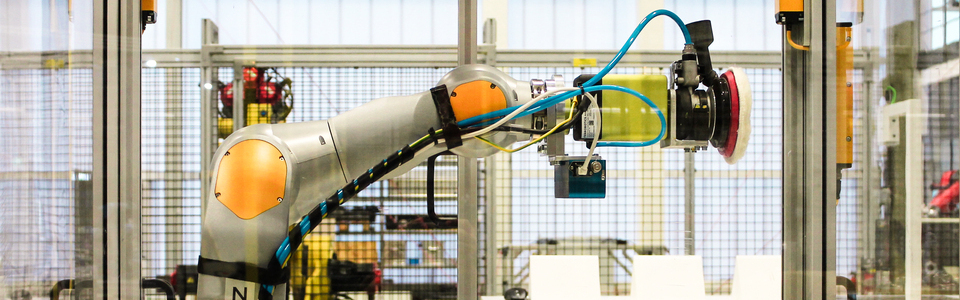

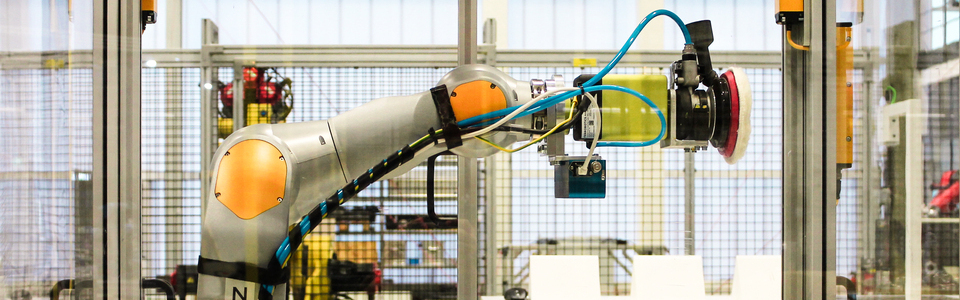

Open source software is increasingly becoming a driver of innovation. By using existing software, companies can quickly complete prototype developments and position themselves in the market, even if they only have few resources of their own. ROS (Robot Operating System) is the best known middleware for robotics and has already become established as a standard in research. The manufacturer-independent operating system offers basic but complex robot capabilities such as navigation, motion planning or image processing and enables robots to be used more economically even where small batch sizes are concerned. Fraunhofer IPA is among the pioneers who developed ROS and has played a key role in shaping it since 2009.

The aim of the ROS-Industrial initiative is to make ROS more popular in industry. The initiative currently has more than 70 members worldwide and offers a wide range of networking opportunities in addition to workshops, training courses and the annual ROS Industrial conference in Stuttgart. At the same time, it also provides information on non-technical topics such as liability and licensing issues.

Fraunhofer IPA leads the European branch of the ROS Industrial consortium and is therefore your experienced partner for all matters relating to open source software for robotics. If you join the ROS Industrial consortium, you get to find out about the added value of open source software for robotics and have the opportunity to exchange ideas with like-minded people.

More info Open Source in Robotics

More info ROS-Industrial and possible membership

Xito.one - Platform economy for robotics

The Service Robot Network(SeRoNet) project has created the necessary technical basis for establishing the open, market-ready “xito.one” ecosystem for robot developments. This enables close cooperation between users, system service providers and component manufacturers. The aim is to significantly reduce the effort involved in developing robot solutions by using state-of-the-art model-based engineering tools and an open marketplace on the “xito.one” platform. As an online platform, xito.one is the central point of contact for all stakeholders in the field of robotics and automation. It offers newcomers, system providers and component developers access to relevant business partners and customers. The Toolify Robotics start-up, which is part of the SeRoNet project, operates the platform and ensures the continuation of the project results even after completion of the project.

IPA spin-offs

In the course of our research work, we have been able to develop diverse new technologies and bring them to market - whether through direct collaboration with industrial partners or through the foundation of start-ups whose employees market the technology themselves. Four spin-offs in the last six years bear witness to this successful form of technology transfer. NODE Robotics and Mojin Robotics are also members of the Cyber Valley start-up network and benefit from the large AI research network in the Tübingen and Stuttgart area.

NODE Robotics (founded in Stuttgart in 2020)

NODE Robotics has made a name for itself with its operating system NODE.OS for navigating autonomous mobile robots. It makes fleets of mobile systems more flexible and uses AI-based technologies to optimize traffic flows. NODE.OS is manufacturer-independent and already implemented by several industrial companies.

Premium Robotics (founded in Leinfelden near Stuttgart in 2017)

Premium Robotics’ core areas include gripping, gripper and robot motion control, as well as image processing for locating objects such as goods on pallets.

drag&bot (founded in Stuttgart in 2017)

drag&bot’s vision is to significantly simplify and speed up the programming of industrial robots. The company offers a graphical programming interface which, thanks to a drag-and-drop function, allows different robot capabilities to be combined to create an automatically generated robot program. The software developed at IPA is already being used internationally by manufacturing and industrial companies.

Mojin Robotics (founded in Leinfelden near Stuttgart in 2015)

The company specializes in developing applications with mobile service robots, such as for logistical tasks. Among others, Mojin Robotics uses developments related to the mobile service robot Care-O-Bot®, which was invented at Fraunhofer IPA.