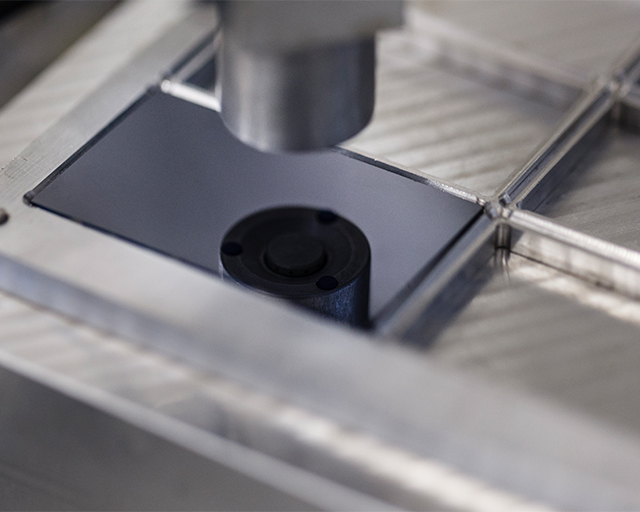

Photovoltaics test centre including: Separation and gripper test, micro-crack detection, FlexPicker, flipper test, conveyor test stand, wafer stacker

A constantly high level of innovation and continuous progress in the research and development of machines, systems and production processes that meet cleanliness standards are the key to future applications. Even the smallest contaminations or damages of the process goods within the value chain can lead to a later failure of the end product and thus to high follow-up costs. To prevent problems, handling processes must be precise and fast, but at the same time gentle and clean. The Fraunhofer IPA offers a comprehensive range of services for the design, analysis and optimisation of such handling processes.