Handling and Feeding

Workpiece carriers and magazining systems for microcomponents

The aim of our application-specific developments is to minimize the number of handling and transfer steps required in manufacturing or assembly processes. To achieve this, we develop optimized, suitable, continuous process solutions based on an analysis of the process chain. In some cases a workpiece or process environment needs to be monitored, or a process requires active support or intervention. To do this, we integrate sensors or actuators into systems. Where possible, systems are constructed as modules to enable their adaption to different components and applications.

- smartWT – smart, process-supporting workpiece carrier system to increase quality and traceability in micromanufacturing processes (funded by the Federal Ministry of Education and Research as part of the cluster of excellence microTEC Südwest). Fraunhofer IPA focuses its developments on systems engineering and system-integrated actuators to enable workpieces to be aligned in a specific way during machining or processing steps.

- IPA.activTray – feasibility study on the additive manufacture of workpiece carriers or receivers with integrated functional elements for actively fixing, positioning and aligning components or substrates.

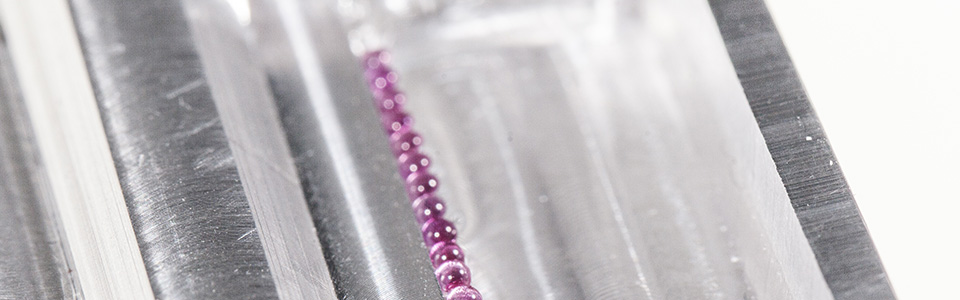

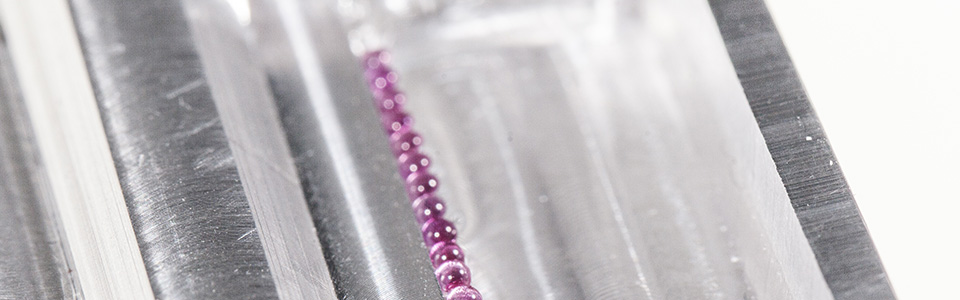

- Modular workpiece carrier with component-specific inserts for receiving and fixing small components

Component singularization and provision

We aim to develop processes that are gentle on components which, due to their size or surface characteristics, stretch the abilities of conventional vibratory feeding systems to their limits.

- IPA.FluidSorting – fluid-based process for microcomponent singularization

Gripping and handling tools

We develop integrated tooling solutions with sensory and active functions to enable the reliable gripping and handling of microcomponents, such as flexible fibers, foils or electronic components

- activTool – assistive tools for older members of staff working in production environments (funded by the Federal Ministry of Education and Research)

The transfer of solutions to standards is supported by our active involvement in norming committees, such as DIN NA »Production equipment for microsystems«.

Our services:

- Surveys and feasibility studies

- Individually-tailored process development and automation

- System development and prototype construction

- Pilot application in the laboratory