Precision Assembly and Application Technologies

Tabbed contents

Expertise

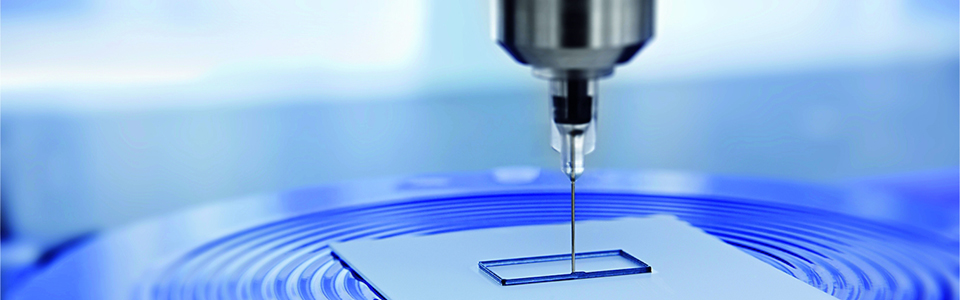

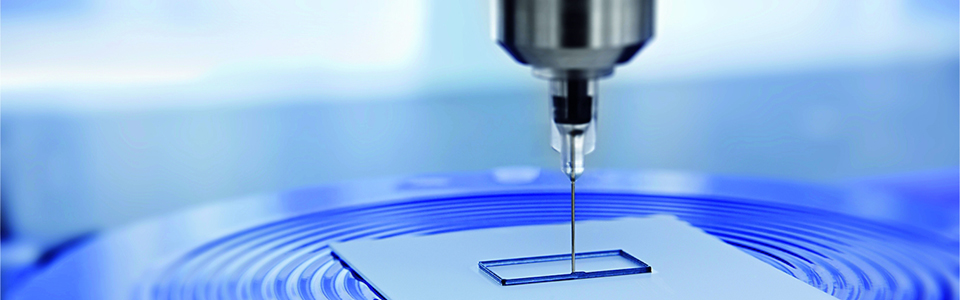

The term microassembly describes the highly-precise, reliable integration of components with dimensions which could be as small as a few micrometers into comparatively large-sized products. The spectrum of microcomponents requiring assembly varies from microchips 250 µm in length, through tiny toothed wheels, to micro-optic fibers as fine as a human hair. These are assembled onto/into an equally wide range of planar or three-dimensional products and substrates, such as highly-integrated printed circuit boards, compact sensor housing or large-sized elements of a machine.

Microassembly not only has to be capable of meeting these demands but also of fulfilling the requirements of high precision while, at the same time, components are becoming more delicate and processes more sensitive.

Fraunhofer IPA has extensive expertise in developing and automating customized, cost-effective process and system solutions, both for the manufacture of prototype components in the laboratory and for step-by-step implementation in serial assembly. The focus of our technological know-how is on the handling, assembly and integration of microcomponents and the precision application of viscous media. In tool technology and systems engineering, we concentrate especially on the aspects of miniaturization and modularization.

Fraunhofer IPA - Ultraclean Technology and Micromanufacturing