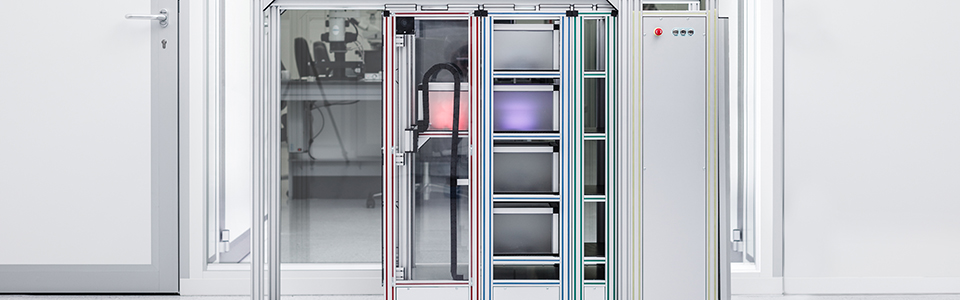

System Miniaturization and Modularization

Tool and equipment modules for microassembly

To create an adaptable, scalable system solution that can be adjusted to the quantity of components to be machined, the level of modularization implemented plays a decisive role. With this in mind, we develop modular concepts and modular system solutions for tools and equipment.

- R&D project: VolProd – manufacturing technology for the cost-effective serial production of microproducts (Reference Number: 16SV5167K)

- Study: µProductionTower – assembly in a new dimension

Miniaturized assembly systems

Standard microassembly systems are relatively large compared to the dimension of the components that need to be processed or assembled. With the aim of adapting the size of systems and economizing on resources, we are pursuing new concepts to miniaturize tools and systems.

- Study: µProductionTower – assembly in a new dimension

Requirements analysis and specification

Especially in microassembly, it is really important to identify and assess the technological requirements of systems and rooms from the economical aspect at an early stage because alterations and additions are usually extremely cost-intensive and time-consuming. We develop methodical procedures and means to analyze and define requirements.

Development and standardization interfaces

The design and layout of mechanical and information interfaces are essential to enable the fast, simple configuration and implementation of system and manufacturing solutions. We develop customized and global interface solutions at all system levels. Where applicable, we also incorporate them in a common standard.

Our services:

- Consulting and conception

- Module and system development

- Prototype construction

- Pilot application in the laboratory

- Support in calls for tenders, project planning and implementation