Applied Coating Technology

Tabbed contents

Our expertise

Besides conducting research into innovative applications and the possible uses of raw paint materials, our key skills in applied coating technology also include developing corrosion protection concepts, determining and optimizing the properties of coatings, analyzing the root causes of coating errors and defects and implementing state-of-the-art testing equipment. In these various areas, we work on industrial and funded projects with a focus on sustainability (use of bio-based raw materials, substitute raw materials, etc.), material and resource efficiency (optimized process parameters, corrosion protection concepts in lightweight engineering, etc.), digitization (suitable material parameters for digital process control) and photocatalysis (methods for improving the quality of indoor air, reducing virus concentrations).

All industrial projects are geared to delivering tailored solutions promptly to the customer and providing support right up to the approval of series production processes. We gain inspiration for new research projects from current problems faced by our customers, new developments in the raw materials industry, new requirements governing products and processes in surface technology as well as new aspects related to environmental protection and work safety.

We have in-depth knowledge of painting technology and the properties of material surfaces. We use this to apply the “right chemistry" for pretreatment and coating materials, to determine the best application and layer formation processes and conduct tests and simulations on the performance of coatings. We also help you implement them in your factory. Furthermore, our expertise encompasses the analysis of the root causes of coating errors and defects along the entire paint and surface technology process chain, the elaboration of expert reports and the development of solutions to rectify them.

Through participation in various committees, we make sure that new legal requirements concerning environmental and occupational safety legislation are implemented promptly in our projects. We work in close collaboration with industrial partners from the chemical industry, paint industry and paint-processing industry as well as from the fields of systems engineering and application and testing technologies. This gives us the necessary insight into practical applications to implement our research results quickly and cost-effectively.

Coating formulation

In this area of expertise, we conduct research on new raw materials or on new fields of application for existing paint raw materials. We implement new coating concepts and raw materials to improve the performance of coatings, develop model formulas and model coatings as well as basic formulas for customers in the coating, printing, and adhesive industries.

Another focus of our work is on research into new application fields, combined with the development of the respective raw material specifications in close collaboration with raw material manufacturers. The potential applications of new raw materials, such as bio-based raw materials, corrosion protection pigments and additives (e.g. filming agents or UV stabilizers) are examined in detail in benchmark studies and screening tests. Our in-depth knowledge of diverse additives used in rheology or as wetting and filming agents allows us to achieve optimal structure/property relationships in line with customer requirements. Because our research is application-oriented, the results obtained are rapidly translated into product applications.

Consulting and development services:

- Development of concepts for innovative raw coating materials with high resistance to weathering and chemicals

- Development of structure/property relationships for coatings, raw coating materials and pretreated surfaces

- Determining possible fields of application for new raw materials

- Development of use-based testing methods for coatings, raw coating materials and pretreated surfaces

- Elaboration of scientific basics and concepts to solve application tasks

- EC dip tank for addressing issues relating to cathodic dip coating processes

- Photocatalysis

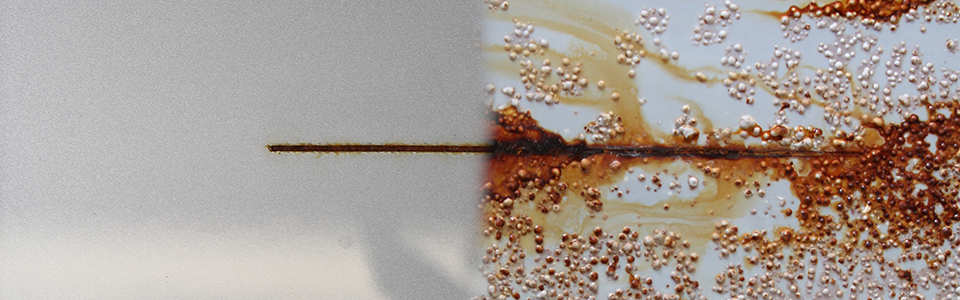

Corrosion protection

Besides being decorative and functional, the most important requirement of a coating is to protect surfaces. The high diversity of materials, ranging from metals, mineral materials through to plastics and composites, means that coatings must fulfil very different and extremely high demands. As well as being adapted to the material and requirement concerned, industrial processes that are both cost-effective and environmentally friendly are also needed to apply these coatings.

Through our research work in this field, we develop corrosion protection concepts based on surface pretreatment processes in line with material requirements. We also apply optimal layer structures with the aim of minimizing the use of materials while simultaneously achieving high resistance to corrosion (durability). The bulk of our work centers around metallic substrates.

We help companies develop and assess coating systems that meet the necessary requirements.

Consulting and development services

- Corrosion protection coatings for steel and galvanized steel in the steel industry

- Studies on corrosion protection pigments and fillers for corrosion protection coatings

- Multi-metal substrates and corrosion protection in the automotive industry

- Surface pretreatment and corrosion protection coatings for aluminum materials

- Development of short-term tests for corrosion protection coatings

- Corrosion protection testing techniques, including conventional methods, new VDA and electrochemical test methods

- Barrier properties of coatings, transportation of water by coatings

- Chemical resistance of coatings

- Development of time-lapse tests

Coating properties

In this area of expertise, the emphasis is on assessing and further developing the properties of coatings. For one, we determine the resistance of coatings to aging by performing accelerated tests in the form of lifetime analyses. We have extensive in-depth knowledge and state-of-the-art testing equipment at our disposal for dealing with matters relating to artificial weathering, coating compatibility, climate change tests and corrosion tests. We also develop and optimize functional surface properties (smart surfaces) such as self-healing, easy-to-clean, anti-fouling, photocatalytic and switchable surfaces.

Consulting and development services

- Determination of the resistance / durability of coatings under realistic test setups

- Coating compatibility tests

- Corrosion tests (accredited)

- Weathering tests

- Climate change tests

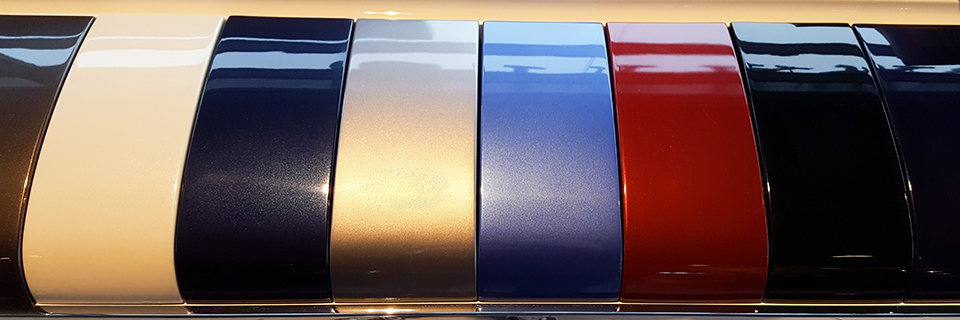

- Colorimetric studies

- Determination of photocatalytic properties

- Development and application potential of functional surfaces

- Approval tests adapted to customer specifications

Damage analysis

A further focus of the work carried out by the Applied Coating Technology group is on damage analysis. Researching into the root causes of coating errors, defects and damage and developing repair concepts will improve products in the long term. After a problem has been identified and its cause eliminated by corrective measures, we provide comprehensive process support that includes quality control during production once the measures are in force. This enables similar mistakes to be avoided in the future.

We advise industrial partners and experts on application-related issues in coating technology.

Consulting and development services

Damage analysis:

- Research into the causes of errors, defects, and damage in all stages of surface and coating technology

- Analysis of the status quo through surface analysis (layer structures and interfaces)

- Reconstruction of the damage pattern

- Development of measures to eliminate errors and defects

Expert reports and studies:

- Technology studies to select optimal coating concepts

- Development of repair concepts

- Benchmark studies

- Preparation of expert reports