Wet Application and Simulation Technology

The working group “Wet Application and Simulation Technology” conducts analyses, further developments and tests on coating methods (focus: spraying) under realistic production conditions. The institute has its very own excellently equipped pilot plant, which also includes painting robots. Here, practical tests can be conducted to assess the operating behavior of application and drying systems and their peripheral equipment when applying any type of paint, especially new coating materials.

The MikroCoat system is a special facility for selectively coating materials without the need for masking. Thanks to precise robot technology, various application modules can be used to apply spot coatings or coatings applied in sharply defined areas.

Optical measuring techniques (LDA, PDA, Fraunhofer spectrometry, laser light sectioning), can be used for spray-jet testing. Measuring devices for characterizing the paint layers produced and for recording coating thickness are also part of the equipment.

The entire painting process chain is also mapped virtually by numerical simulations (especially fluid dynamics), with the real pilot plant tests and the computer simulations supporting each other.

Expertise

Painting pilot plant

The variable painting line combines the demands of industry with modern scientific analysis methods. The painting line also meets the cleanliness, climate and airflow requirements of the automotive industry (e.g. air sink rate 0.1-0.5 m/s, heatable and humidifiable). Three painting zones with robot technology are fitted with independent ventilation systems and paint separation systems. Thanks to their adaptable design, they can be used for a wide range of applications, from coating vehicles and ships right down to small parts.

All liquid paint materials (solvent-based paints, 2K paints, water-based paints, powder slurries, UV-curing systems, nano materials, even suspensions such as enamel slurries) can be processed.

Off-line programming and the conversion of robot programs (in each case via external service companies) are possible, as is also teach-in. The robots are fully equipped with process technology. Furthermore, a range of adaptable lifting devices and other manipulators is available.

Additional mobile, modular application equipment (dosing technology, also 2K, process ventilation, speed control, etc.) enables rapid adaptation to the respective task. The spectrum ranges from simple process control valves to PLC-controlled application equipment and bus-compatible systems.

Range of services:

- Determination and evaluation of various application-specific parameters for process optimization, as well as input variables for numerical process simulation, also by means of statistical test planning

- Coating thickness distribution, coating efficiency, appearance, etc.

- Particle size distributions and particle velocities using laser-optical methods, visualization with high-speed camera

- Characterization of paint materials; parameters such as density, solids, rheology

- Preparation of samples for advanced technology tests

- Primas system for determining process parameters

- Reconstruction of complete painting processes, incl. pre-treatment and drying

- Use of original workpieces possible; project examples: car bodies or body components (e.g. doors), windscreen wiper arms, engine blocks, shock absorbers, aircraft interior parts, television housings, crane segments, small parts such as mobile phone shells, filters, roof tiles

- Development of atomizers, system components and application concepts

- Validation of assemblies (atomizers and components, cleaning devices, etc.)

- Feasibility studies (innovative technologies, new production processes)

- Presentation of process alternatives, taking all relevant general constraints into account (cycle times, material and energy requirements, cost calculation, etc.)

Optical metrology

Fraunhofer IPA’s aim is to characterize the atomization process as comprehensively as possible under real conditions. For this purpose, optical measuring methods are used to monitor spray painting processes. Furthermore, parameter influences are identified and characterized in detail, both qualitatively and quantitatively, and basic knowledge of the physical processes is gained.

This is often necessary if manual coating processes are automated and innovative atomization techniques, such as high-speed rotation atomizers, are to be used at the same time.

The following technologies are implemented at Fraunhofer IPA:

This is one of the oldest and widespread methods and is based on the fact that particles or droplets, depending on their size, diffract a laser beam to different degrees, regardless of whether the particles are opaque or transparent. The angle of diffraction is inversely proportional to the droplet diameter. The diffracted light is detected by photoelements and the particle size distribution is calculated. The method always provides an integral value for the entire cross-section of the spray jet.

While, due to the rotationally symmetrical spray cone, a single-point measurement is often sufficient for high-speed rotation atomizers, multi-point (grid) measurements are usually carried out for air and airless atomizers.

Laser Doppler Anemometry (LDA) (particle velocity)

This method is used for the point-by-point determination (high local resolution) of velocity components in fluid flows. Here, a laser beam is split into two beams by a beam splitter. These beams cross again at the measuring point, creating an interference fringe pattern. The frequency of this scattered light signal is proportional to the velocity component.

Phase Doppler Anemometry (PDA) (particle size and velocity)

With this method, the size of individual droplets can be determined in addition to their velocity (see LDA). To do this, a second laser beam is used. Several photodetectors use the additional information contained in the phase position to calculate the radius of curvature and from this the particle diameter.

Laser light section (particle and air movement)

The laser beam is formed into a line fan with Gaussian intensity distribution along the line. This allows a defined section plane to be illuminated and particle paths and deposition behavior of paint spray to be qualitatively visualized.

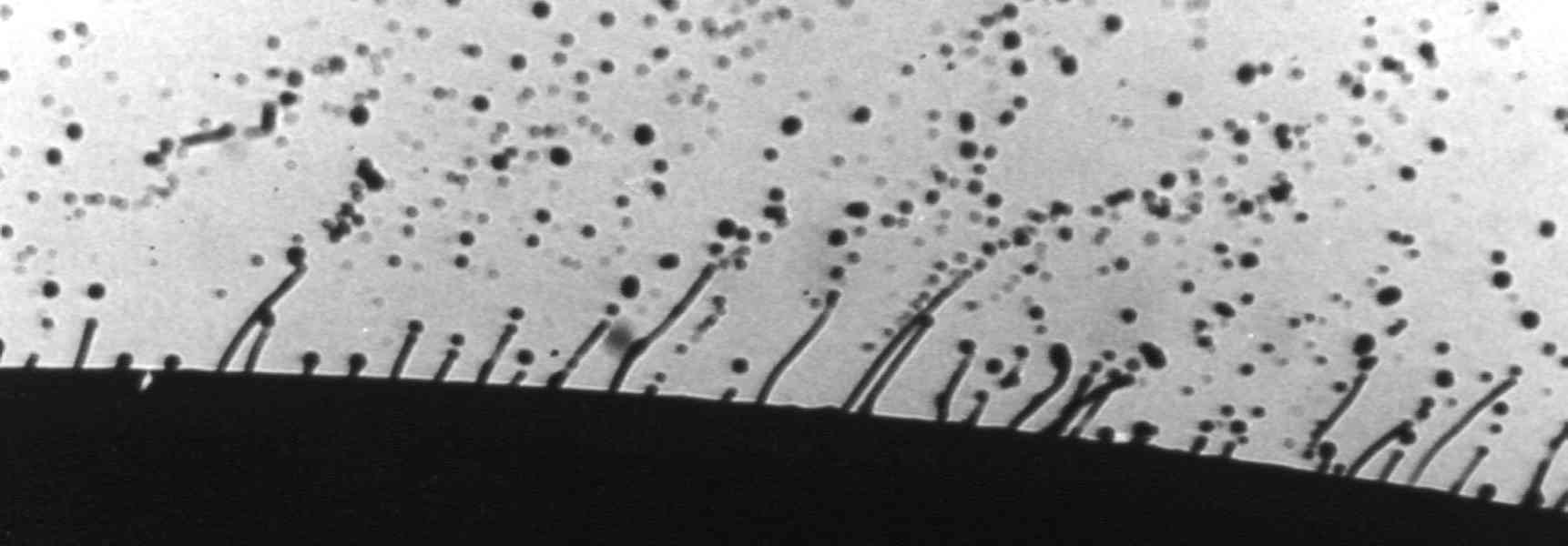

Stroboscopic illumination methods (visualization)

These are pulsed light flash lamps that emit strong light pulses in the nanosecond range which are used to visualize atomization processes (filament, lamella and droplet formation). Due to the extremely short pulses, highly dynamic processes are “frozen” and can be recorded with conventional CCD cameras. In addition, phenomena such as the wetting of distribution discs can be displayed, e.g. using bell discs.

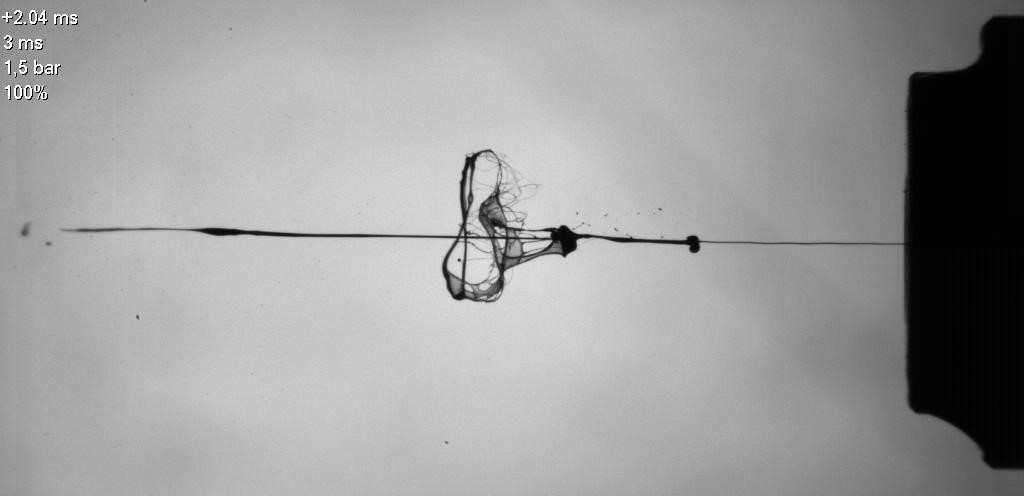

High-speed camera (atomization dynamics)

Phenomena can be visualized dynamically using a high-speed camera. The obvious advantage here is that processes can be visualized and evaluated continuously.

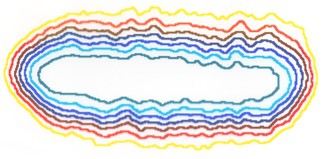

Image processing systems

Here, “real” spray images are generated, either as a static image or as a dynamic one (coating with a single web). These are evaluated by image processing to assess the layer thickness and symmetry. This provides information, for example, about damaged air caps (e.g. due to collision) or clogged air holes (e.g. due to negligent cleaning).

Overspray-free painting

The paint mist that is generated during spray painting - overspray - must be removed from the air in the booth. This is therefore the reason behind the complex equipment and high energy consumption needed to condition the booth air. In the case of multi-color painting, manual masking work is required, which makes the process both time-consuming and cost intensive.

Fraunhofer IPA addresses these aspects with the MikroCoat system, a development that enables users from different industries to implement innovative, loss-free painting processes without the need for masking.

The heart of the system is a 6-axis robot with exceptionally high repeatability. The robot is housed in a cabin with an adjustable volume of supply and exhaust air to reliably extract solvents and particles.

Diverse application modules can be adapted to the robot, e.g.: LineMaker

The coating material is applied to the surface using round or flat nozzles or, alternatively, transfer materials such as foam or fleece. The quantity is adjusted via a dosing unit, which produces very fine lines with a sharply defined edge. This makes it possible, for example, to apply multicolor coatings to components of different shapes without the additional steps of masking and unmasking.

Piezo jet valve

With this application module, free-flying drops of the material are generated over a few millimeters to centimeters, which then hit the surface with pinpoint accuracy. In contrast to conventional inkjet printing, this allows a wide range of coating materials to be processed, from low-viscosity to high-viscosity. The use of ceramic parts means that abrasive coating materials can be applied.

Precision atomizer

The airbrush atomizer used in the graphic design sector has been extended by a linear drive. This enables it to be adapted to a robot. Coating materials up to approx. 100 mPas can be micro-dosed and applied with pinpoint accuracy. The spray jet can be as narrow as 2 mm, with a blurring range of 30 %. The fine spray also allows very thin coatings <1 μm to be applied evenly and precisely.

Paint wetting impairment substances

Paint Wetting Impairment Substances (PWIS) can lead to severe coating defects when paints are applied, resulting in high costs due to rework or troubleshooting and eliminating the cause.

The causes are contamination of the substrate to be coated, of the paint material or of the freshly coated surface by substances which reduce the surface tension at the level of the substrate/paint interface and thus impair the coating process. This results in the formation of craters, wetting problems over large areas or swelling.

Substances that potentially impair paint wetting include silicones, oils, greases, plasticizers and release agents. However, this issue not only concerns all substances, plant components and auxiliary materials used in the production process, but also, for example, work clothing and protective equipment as well as cosmetics, hairdressing products or perfumes used by employees. Paint wetting problems can also be caused by the transfer of such substances from other production areas or purchased parts.

However, these substances do not necessarily lead to paint wetting problems and should therefore not be banned from the paint shop across the board. Instead, all substances and components used in the paint processing environment should be tested for paint-wetting impairment substances in advance.

Through the careful and critical consideration of the components, materials and processes used, and the thorough training of employees, also with regard to the topic of PWIS, many causes of crater formation and wetting problems can be ruled out and process reliability significantly improved.

At Fraunhofer IPA, tests on paint wetting impairment substances are carried out in accordance with VDMA 24364, MBN 10494-3 and, if required, according to other specifications. To maximize traceability and reproducibility, Fraunhofer IPA has been accredited by the German accreditation body DAkkS for testing paint compatibility in accordance with DIN EN ISO/IEC 17025.

In addition, we offer advisory and training services on the subject of substances that impair paint wetting.

Painting simulations

Numerical simulations can be conducted on all process steps and offer the following advantages:

- Minimizes complex and expensive experimental tests

- Fast execution of parameter studies and optimization measures

- Supports planning processes

- Quick insight into the fundamental steps of the painting process and visualization of non-measurable variables

- Fast transfer from the model to the real situation

- Improved process reliability

Thanks to our experience in the correct use and selection of suitable tools, it makes economic sense even for small companies to commission numerical simulations.

At Fraunhofer IPA, we have adapted the method of simulating flow processes and electric fields to the requirements of painting technology and introduced it as a tool for research, development and application. For this purpose, commercial CFD tools are supplemented by modules for calculating particle paths as well as layer thickness distribution and application efficiency in coating arbitrary geometries.

A computer program, also developed in-house, enables us to simulate dynamic coating processes on complex three-dimensional workpieces. Here, the previously calculated static spray pattern is integrated along a specified coating path.

All methods are validated in the pilot plant and tested for their practical suitability.

Examples of successful use of numerical painting simulations at IPA include:

- Flow in atomizers

- Overspray and solvent dispersion

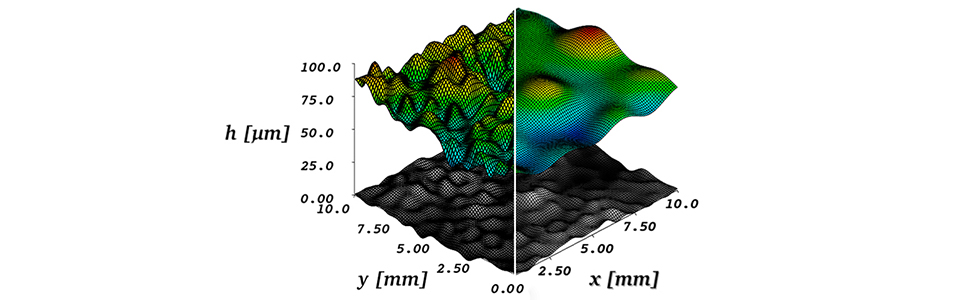

- Film formation and paint film flow

- Powder coating with powder gun and fluidized bed

- Pneumatic feed of powder coatings

- Paint film drying, temperature profile in paint layers

- 2-component mixer

- Seam sealing

- Droplet separator

- Thoracic particles

Paint drying

Paint drying by convection, IR radiation or UV radiation is a key process in painting technology. Due to the high energy, time and space requirements, it is important to optimize this process. Through simulations, energy consumption can be minimized, heating processes can be compared, and residual moisture can be calculated. The simulations are carried out by means of complete fluid-dynamic calculations, taking convection and heat radiation into account.

Spray painting

Aims and tasks

Spray painting processes are characterized by relatively large paint material losses and high energy consumption. On the one hand, the overspray - i.e. the paint particles not deposited on the workpiece - impairs the coating quality due to contamination of the workpiece. On the other hand, plant engineering is confronted with major challenges if paint recycling and environmentally friendly painting systems are to be used to lower energy consumption and thus CO2 emissions.

What we can do for you

We help you plan, implement as well as optimize coating systems for your task. For example, we can:

- Calculate solvent concentrations and dust emissions in recirculation mode, taking the coating throughput in the application into account.

- Optimize the booth flow

- Optimize the filter for particle separation

In our laboratories, we have excellent equipment for conducting spray coating tests, such as various atomizers for painting applications, laser diffraction spectrometers, laser Doppler and phase Doppler anemometers for characterizing the particle phase, laser light sectioning methods for visualizing flows and Nanolite® point spark lamps for observing the atomization process. These enable us to carry out complex investigations promptly and determine the necessary input conditions for numerical simulations.

Flow simulation

Fields of application

Flow analysis, flow optimization, quality assurance, Newtonian and thixotropic coatings

Initial situation

The term “flow” describes the property of coating films to automatically compensate for any unevenness arising during application. If the flow is incomplete, the surface of the coating film has a more or less pronounced “orange peel” structure after drying.

Our services

With the simulation tools developed at Fraunhofer IPA, we can calculate the flow from measured paint properties (rheological properties, surface tension, evaporation rate if applicable). The simulations can speed up the development and introduction of new coatings and improve the achievable flow result. Simulations can be used to predict flow behavior and explain observed differences in the flow behavior of different formulations or batches. Furthermore, they reveal how the coating properties have to be modified in order to achieve a surface structure that is closer to the desired structure.

Procedure

- Determination of the actual state: we measure coating properties and, if necessary, other process conditions

- Simulations: film waviness during spray application (so-called initial mountains); real measured paint properties are converted into process-relevant properties

- Conclusions: we explain the actual flow result and make recommendations to modify coating properties.

UV and cleaning simulation

Fields of application

PC-operated simulation for optimizing UV curing processes

Initial situation

When designing new UV curing systems or modifying components, it must be ensured that each surface element of the component is reached with the necessary intensity or dose.

Our services

For manufacturers and users of UV curing systems, Fraunhofer IPA can carry out an analysis of their current process with the software and make a corresponding graphic evaluation.

Advantages of the simulation:

- Development support for new system concepts

- Decision support in the design phase

- Confirmation, control and enrichment of experience

- Aids exchange with manufacturers, technicians and decision-makers

- Stable processes

- Feasibility check

- Visual argumentation aid for customer acquisition

- Can be extended to cleaning and painting processes

Test facility

The project aims at avoiding the complex illumination equipment (arrangement of spotlights, movement of object and spotlight) for complex three-dimensional objects. The idea is derived from the integrating sphere, which distributes the light from the spotlight evenly by diffuse reflection from the inside of the sphere, thus ensuring optimum illumination for any object.

A unique feature of the system is that the new technology eliminates the need to move the component or the spotlight during the curing process. Spotlights and reflectors are arranged in such a way that a centrally placed component is always ideally illuminated. The simulations were used to aid the design of the system and to determine parameters such as irradiation time, number and position of components. This resulted in a successful test set-up, which can be made available to customers on request for testing purposes.

Project

In the project “UV ball pulse system for curing 3D paints” funded by the Federal Ministry for Economic Affairs and Energy as part of the Central Innovation Promotion for SMEs (ZIM) and supervised by the AiF-Projekt GmbH, the software mentioned was able to confirm, among other things, the suitability of a new type of UV curing system for use in industry. Based on an idea by Mr. Rainer Röck and the project partners Durst Lackier- und Trocknungsanlagen GmbH, EASYTEC GmbH, Fraunhofer IPA, Opsytec Dr. Gröbel GmbH, Ritzi Lackiertechnik GmbH and the University of Stuttgart’s Institute of Industrial Manufacturing and Management IFF, it was possible to set up a functioning pilot plant in close cooperation with the partners.

Industrial parts cleaning

Fields of application

Spray jet cleaning, sand blasting or similar processes

Initial situation

When designing such cleaning systems, the various modules must be arranged and aligned in a suitable way around the workpiece. Otherwise, shadow zones will occur, or the part will be over- or under-treated.

Our services

In the course of our research work, we have developed a PC-operated software program for optimally designing process sequences in these cleaning machines - both wheel blasting and compressed air blasting. The blasting effect of the system on the specific components can be quickly calculated and virtually displayed in order to tap optimization potential and avoid shadowing. Special customer requirements can be examined for feasibility with the simulation program and modifications can be made accordingly to optimize the system.

Procedure

In a maximum of 6 simulation steps, your machine can be designed efficiently:

- Two-day instruction course for non-CAD-trained personnel on how to use the program using own factory component.

- CAD data in STP file format - alternatively 3D scan of the component

- Current layout of the system: component geometry, nozzle type/positions/number/orientation, kinematics

- Initial analysis of the current layout and determination of potential for optimization

- Feasibility check and efficiency analysis

- Transfer to machine to be implemented

PC-operated simulation of coating processes

Aims and tasks

Detailed models and numerical simulations of technical processes make a significant contribution to the virtual factory. With the software solution developed at Fraunhofer IPA, the painting process can be optimized with regard to different parameter settings and path guidance and made available to a wide range of users thanks to virtual reality methods.

To simulate and visualize complex three-dimensional painting processes, it is essential to understand and calculate stationary, static subprocesses. The following processes can be simulated:

- electrostatic painting,

- pneumatic painting,

- powder coating and

- cathodic dip coating.

With the various simulation models adapted to the respective application, the particle transport can be calculated as a function of the fluid mechanics, as well as electrodynamics, thermodynamics and specific coating properties. This enables the distribution of coating thickness to be determined.

Features

The program provides detailed insight into the process and the anticipated result:

- Time-dependent analysis of the process flow

- Parameter studies

- Process optimization

- Interfaces for data exchange