Automation Potential Analysis (APA)

Your systematic start to automation

Would you like to...

- counter the shortage of skilled workers by using technology?

- improve productivity in your factory by using robots?

- automate more processes in your company, but don't know where to start?

- move away from manual assembly, but don't think your processes are automation-friendly?

Then APA is just what you need.

Identifying automation potential quickly and methodically

In some areas of manufacturing, such as welding and assembly, many processes are still carried out manually owing to specific requirements for an automation solution. However, with the appropriate knowledge and a systematic analysis of the individual processes, those processes that can be automated in a technically and economically viable manner can soon be identified.

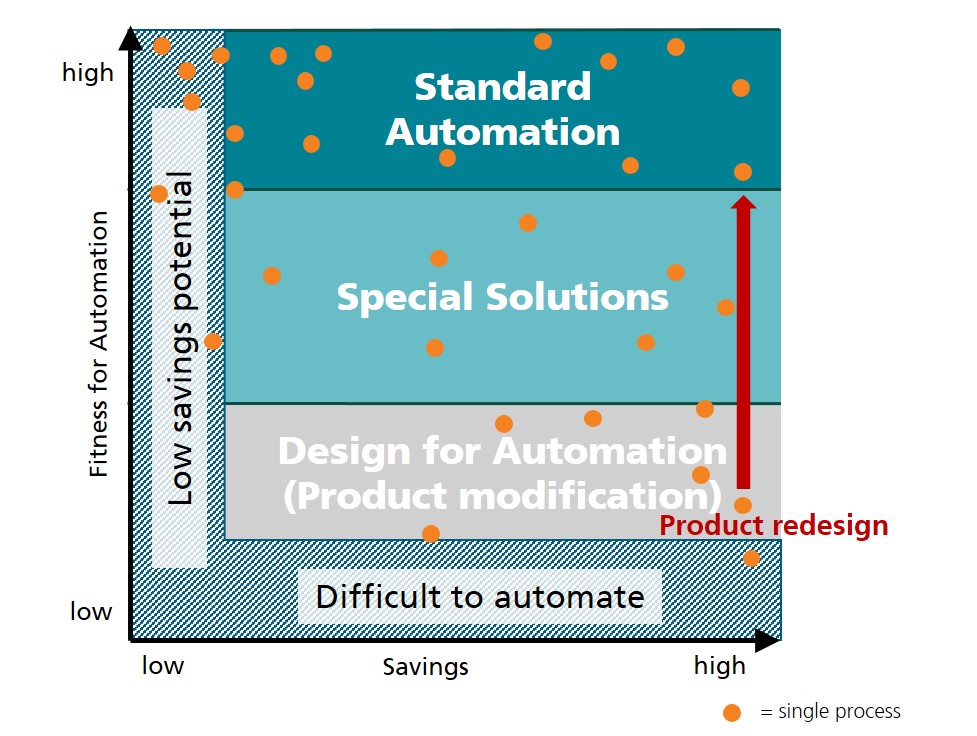

With this in mind, Fraunhofer IPA has developed Automation Potential Analysis (APA). Based on specific criteria, the automation experts check each process's Fitness for Automation and weight various criteria according to customer requirements. The result of this analysis is a recommendation for full or partial automation and, where appropriate, a solution with human-robot collaboration (HRC). The methodology has already been applied in more than 500 customer projects worldwide.

Better Fitness for Automation through Design for Automation

Another way to make production more efficient is to design products in a more automation-friendly way from the aspect of Design for Automation. And in cases where the APA result shows that (partial) automation is not worthwhile, Design for Automation can often improve even manual assembly operations and reduce errors.

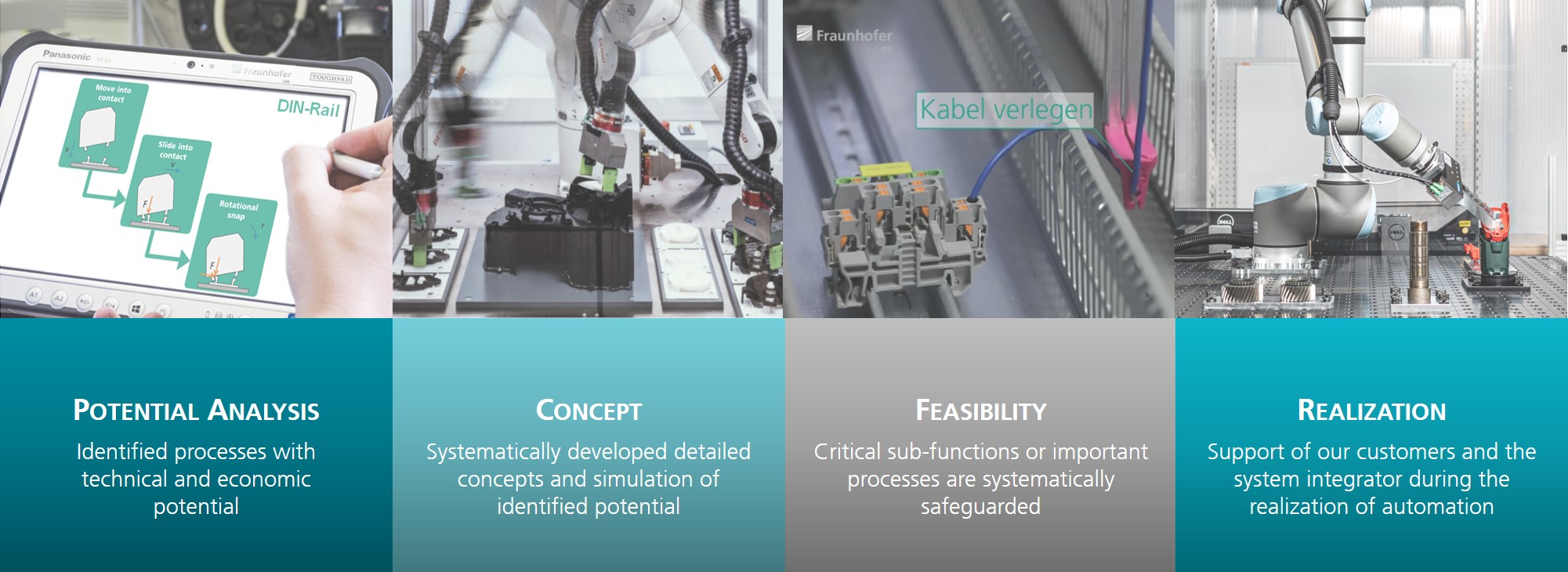

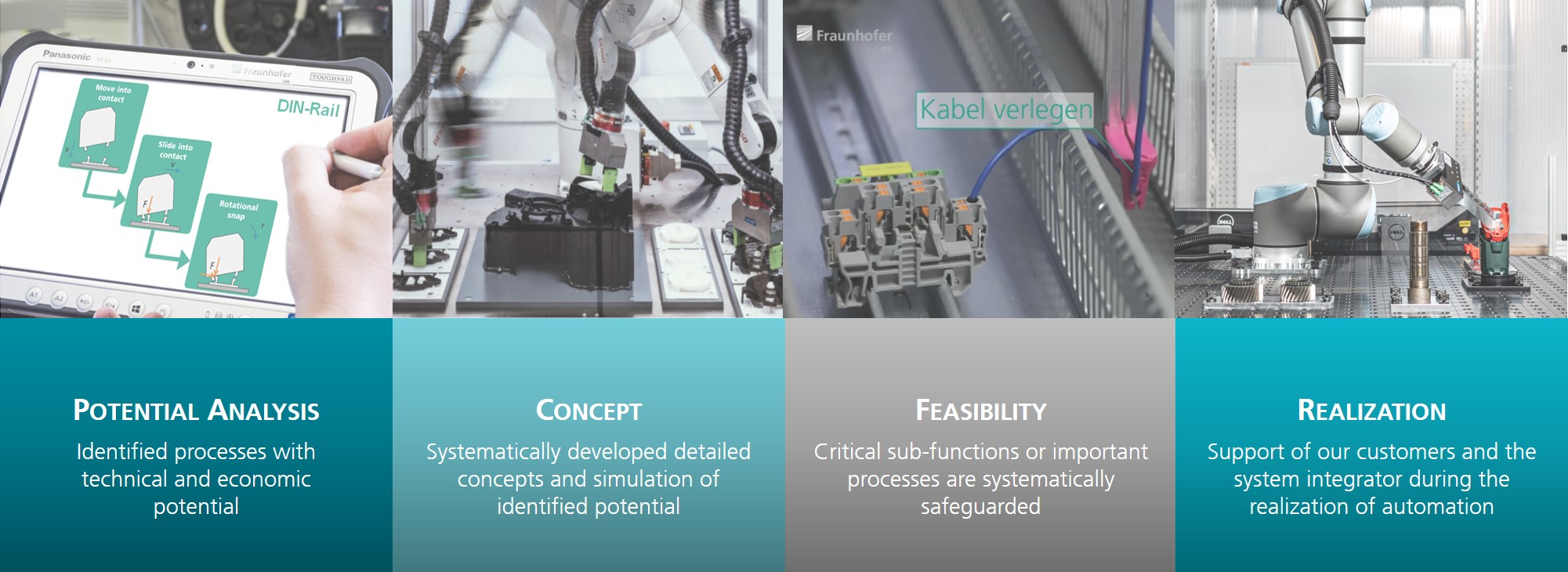

Services

- Together with you in workshops and directly in your production facility, our automation experts analyze the current situation for the process categories of assembly and welding

- We analyze each process step to ascertain the technical and economic feasibility of automating them

- We identify the processes that can be automated and recommend actions to improve their suitability for automation

- Optional: Product design and process design optimization

- Optional: Development of automation concepts

- Optional: Feasibility studies for systematically safeguarding critical sub-functions

Advantages

- Automation potential is systematically determined

- “Hidden capacities” are identified by automating processes

- Cost-effective solution, be it fully or partially automated or with human-robot collaboration

APA in assembly

In many manufacturing companies, assembly tasks are still performed manually. The reasons for this are a large number of variants with small batch sizes, highly diverse assembly processes, and a parts supply that is difficult to automate. Nevertheless, rationalization potential in assembly operations can often still be tapped through automation, thus enabling goods to be manufactured at lower cost.

During an APA, the assembly processes are recorded chronologically. For each step, the way parts are supplied and the assembly process itself are documented. Using the analysis tool, each of the assembly processes considered is evaluated not only for its technical feasibility in terms of separation, handling, positioning and joining, but also for potential cost savings. The result is an easy-to-understand documented assessment of the feasibility of automating each of the assembly steps examined.

APA for welding

In many manufacturing companies, welding tasks are still performed manually. The reasons for this are a large number of variants with small batch sizes, and a parts supply that is difficult to automate. Nevertheless, even here, automation can often be used to counter the shortage of skilled workers, to tap rationalization potential and thus to manufacture goods at lower cost.

During an APA, the processes are recorded chronologically. For each step, the way parts are supplied, tack welding, as well as welding processes and finishing tasks are documented. Using the analysis tool, each of the processes considered is evaluated not only for its technical feasibility but also for potential cost savings. The result is an easy-to-understand documented assessment of the feasibility of automating each of the process steps examined.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyAPA in intralogistics

Manual processes are quite common in intralogistics, partly because automated guided vehicles (AGVs) are still a relatively new technology. This is mostly due to the diverse range of parts that need to be transported in a company. An Automation Potential Analysis (APA) enables the identification of potential streamlining opportunities in order to cut costs in the factory.

With an APA, we analyze your internal supply orders one by one. For each process, we establish the origin and nature of the order and document the transported goods as well as the surrounding conditions in which the delivery order is carried out. Using the analysis tool, each of the processes considered is evaluated both for its technical feasibility and for potential cost savings. The result is an easy-to-understand documented assessment of the feasibility of automating each of the process orders examined.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyAPA – The App

For an objective and reproducible analysis of your processes, we utilize the new APA-App for our Automation Potentialanalysis at your site. For this purpose, our validation sheets specially developed for a variety of processes have been integrated into the app (see previous tabs). By using this method, we precisely identify the “Fitness for Automation” of individual processes and thus determine the automation potential of your production processes.

The APA app will also be available for you soon. Thus, you can analyze the processes at your production site independently or with the support of specialists from the IPA.

If you are interested in the app or our service, please feel free to contact us!

Design for Automation

Design for Automation (DfA) describes the way a product is designed with the aim of making it suitable not only for automated assembly but also automated disassembly. Because humans have such a wide range of skills, they are capable of putting parts together that are difficult to assemble and disassembling them again in exactly the same way. Unfortunately, this is rarely the case with automation processes. DfA is all about making it possible to assemble even complex products automatically with little or no human intervention.

Design for Automation thus goes a step further than Design for X (e.g. Design for Assembly), which considers product design suitable for assembly in general terms.

The rules of assembly-oriented design are also found in Design for Automation but in this case the aspect of automation is also taken into account. If something can be joined or separated well using automated processes, then it can also be joined or separated well using manual processes. A DfA workshop thus yields important results even if no automation solution is recommended at the end.

Find out more about the DfA reference project using the example of an electric motor with FERTIG Motors GmbH and Fraunhofer IPA.