Cleaning Robots

Tabbed contents

Expertise

General information

Despite being monotonous and repetitive, cleaning tasks still tend to be carried out by hand. However, manually operated cleaning devices involve high staffing costs, including the necessary training and operating time. Due to significant staff fluctuation rates in the cleaning industry, a lot of time is spent on showing workers how to operate these devices. In addition to this, the demographic change is causing fewer and fewer trained cleaning staff to be available on the employment market. Also, in areas where security is an issue, workers must be especially trustworthy. Furthermore, the increasing complexity of state-of-the-art architectures means that more and more areas in buildings where cleaning staff work are becoming extremely difficult or even impossible to reach.

This is where autonomous cleaning solutions come into play. They could also be implemented in industrial or hazardous environments, or where cleaning devices pose a threat to humans. An autonomous cleaning machine would therefore significantly lower safety risks. Disinfection tasks carried out to combat the coronavirus or other circulating pathogens would also be suited well for automization. As a result, staff would not be exposed to potential infection hazards and disinfection tasks could be performed continuously, for example overnight.

Expertise and sample projects

For many years, Fraunhofer IPA has been involved in developing relevant key technologies for cleaning robots. The focus is not only on the acquisition of cleaning parameters via sensors but also on the development of robotic hardware specifically adapted to the case in question.

- In the “AutoPnP” project, Fraunhofer IPA developed unique novel solutions for service robots to clean office buildings. To achieve this, the Care-O-bot® 3 robot assistant was equipped with capabilities for cleaning floors in a specific way and emptying wastebaskets automatically.

- In the “BakeR” project, the developments from AutoPnP were transferred to a specialized, modular cleaning robot and further refined. Besides modular robot hardware, practical software components for surface coverage and dirt or object detection were developed and successfully tested in practice.

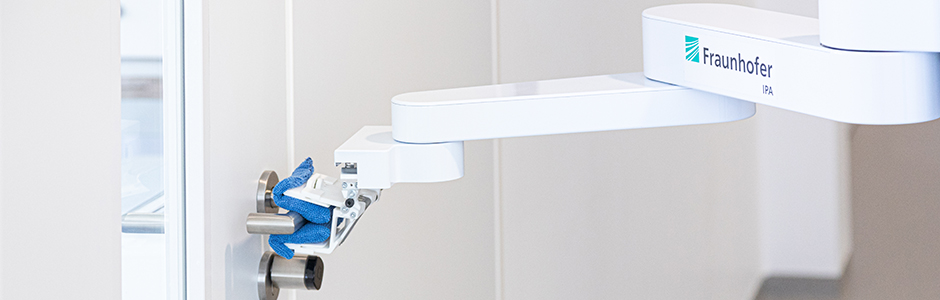

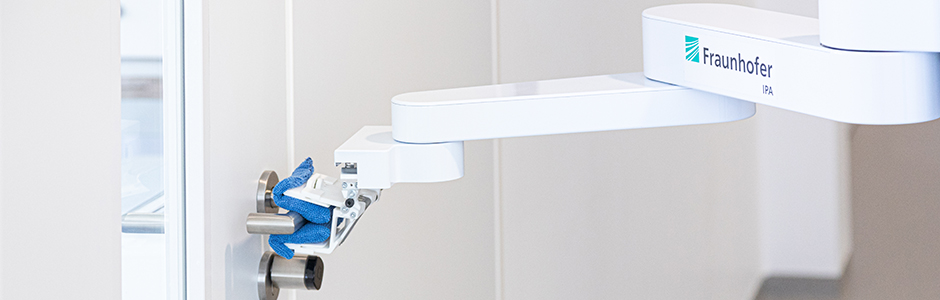

- In response to the coronavirus pandemic, several departments at Fraunhofer IPA developed the mobile cleaning and disinfection robot “DeKonBot”. It advances autonomously to potentially contaminated objects such as door handles, light switches or elevator buttons and disinfects them using an efficient scrubbing/wiping motion. Thanks to a newly developed 3D sensor and automatic recognition of the objects to be cleaned, the robot can be put into operation in a new environment within a very short time.

- In the “MobDi” - mobile disinfection project, Fraunhofer IPA was working together with ten other Fraunhofer institutes to further develop the technologies of DeKonBot. Specifically, the robot “DeKonBot 2” was developed, which is more compact, flexible and closer to a product than its predecessor. With its cleaning brushes, the robot removes soiling from the objects to be cleaned and at the same time applies disinfectant to the entire surface.

- Specific further development of the robot for healthcare institutions is goal of the “RoReBO” project. Among others, new adaptive cleaning tools will be developed. The abilities of the robot will be extended towards disinfection of additional objects in hospitals. The automatic opening of doors is also addressed in the project.

Further experience in the field of cleaning robotics for the consumer sector can be drawn upon when it comes to using cost-effective hardware components and correspondingly efficient processing methods.

Services

- Analysis of cleaning tasks, documentation of general constraints and requirements

- Design of solutions for automated cleaning tasks, execution of pre-tests on critical subsystems, assessment and selection of solutions

- Alignment of interfaces with the overall system or building

- Development and construction; design of software, hardware and electronics

- Implementation (manufacturing, assembly, and programming), initial test runs of subsystems and overall systems in a true-to-life test scenario

- Development of concepts that help to bring product-near prototypes to series-production readiness

- Involvement of industry-relevant companies and user groups in the entire development process

- Safety certification, on-site commissioning, approval processes, user training courses

Videos

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyCleaning and disinfection robot “DeKonBot 2”: Field trial in an office building

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyCleaning and disinfection robot »DeKonBot«