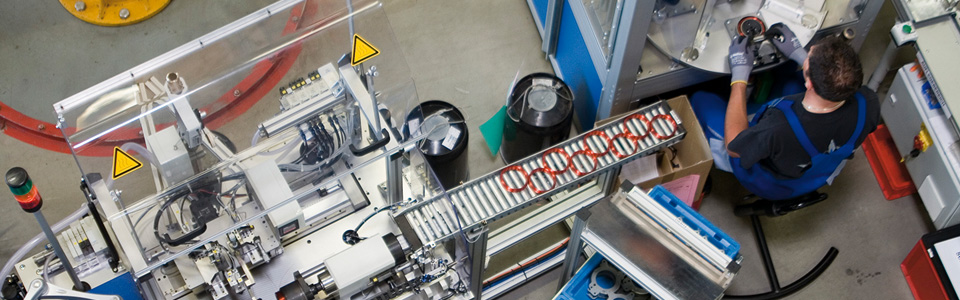

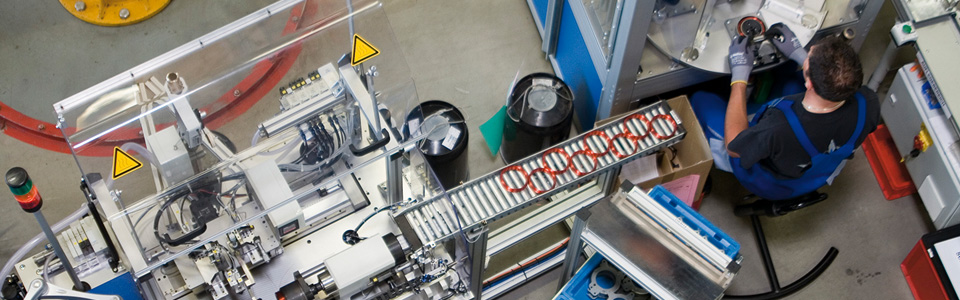

Planning and Development of Robot Systems

Tabbed contents

Expertise

We see ourselves as a neutral competent partner to assist you with the development and implementation of robot systems and automation technologies; whether it be for industrial or service applications, for medium-sized or large-scale enterprises, or for users or component manufacturers.

With 40 years of experience in robotics and automation, multi-disciplinary teams, an unparalleled network, extensive expertise and superbly-equipped laboratories and workshops, we are able to offer a wide range of services:

- Market analyses

- System design

- Feasibility studies

- Simulation of kinematics

- Development of kinematics

- Material flow simulation

- Prototype development

- Realization and implementation support

- Drafting of user requirements and technical specifications

- Tests on robots and systems

- Optimization of existing systems

We would welcome an opportunity to invite you to our institute center in Stuttgart-Vaihingen in Germany. We would also gladly visit you at your company to discuss your requirements.

Videos

COMET - adaptive production systems using industrial robots

SMErobotics Trailer Video