2ndSCIN® – Enabler for Cleanliness-Critical Automation Technology

AI-based production and assembly optimization

Cleanliness is the basis for key technologies - which means ultraclean production is also becoming increasingly important. The use of standard industrial components in the clean room presents a particular challenge. Particles or chemical and biological residues released by the equipment into the environment are particularly problematic. For many manufacturers it is a laborious, time-consuming and cost-intensive process to make their products cleanroom suitable. Rigid enclosures or minienvironments are often used as workaround. Since previous systems did not meet the high cleanliness requirements of industry, researchers at the Fraunhofer IPA looked into the problems and sought a solution.

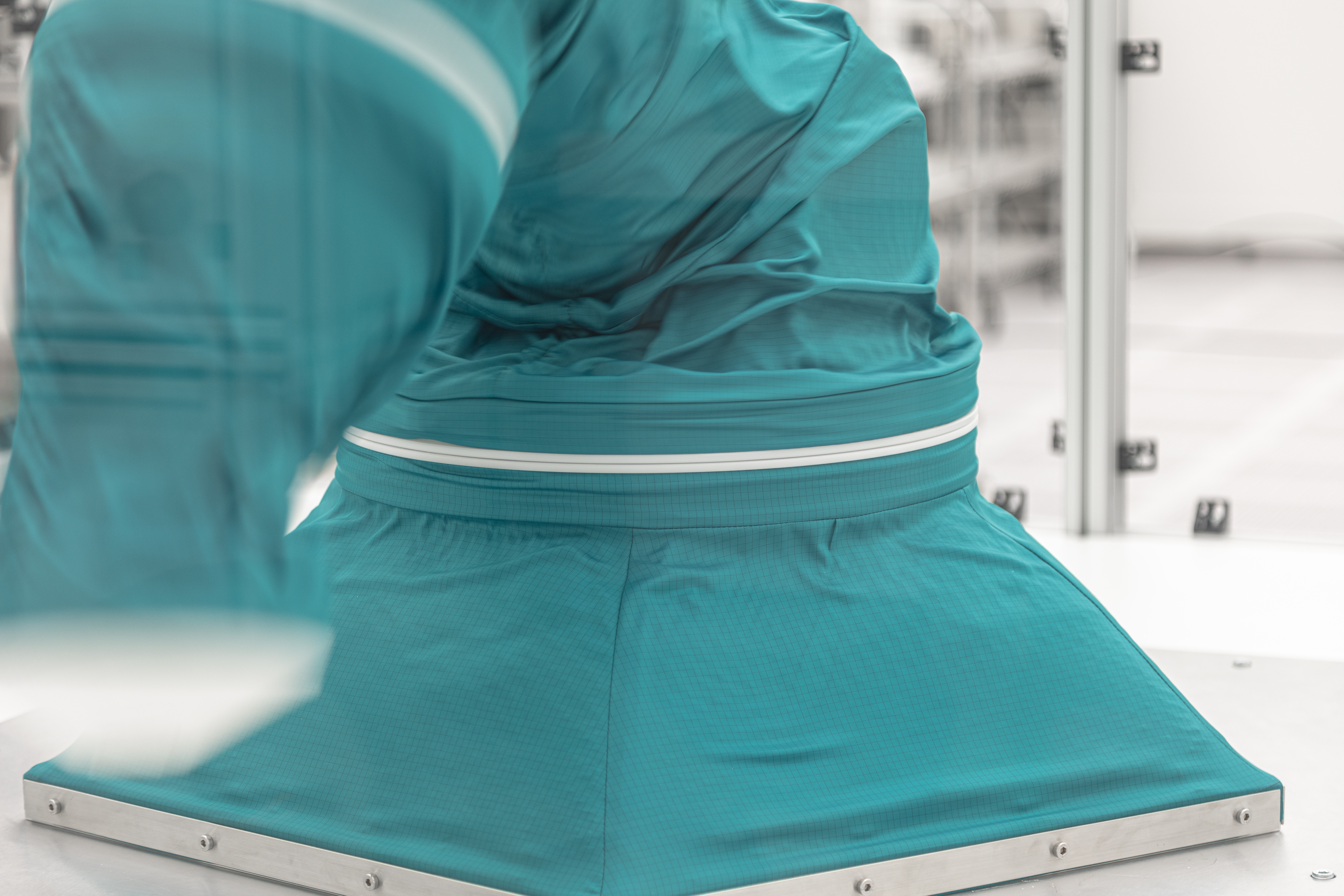

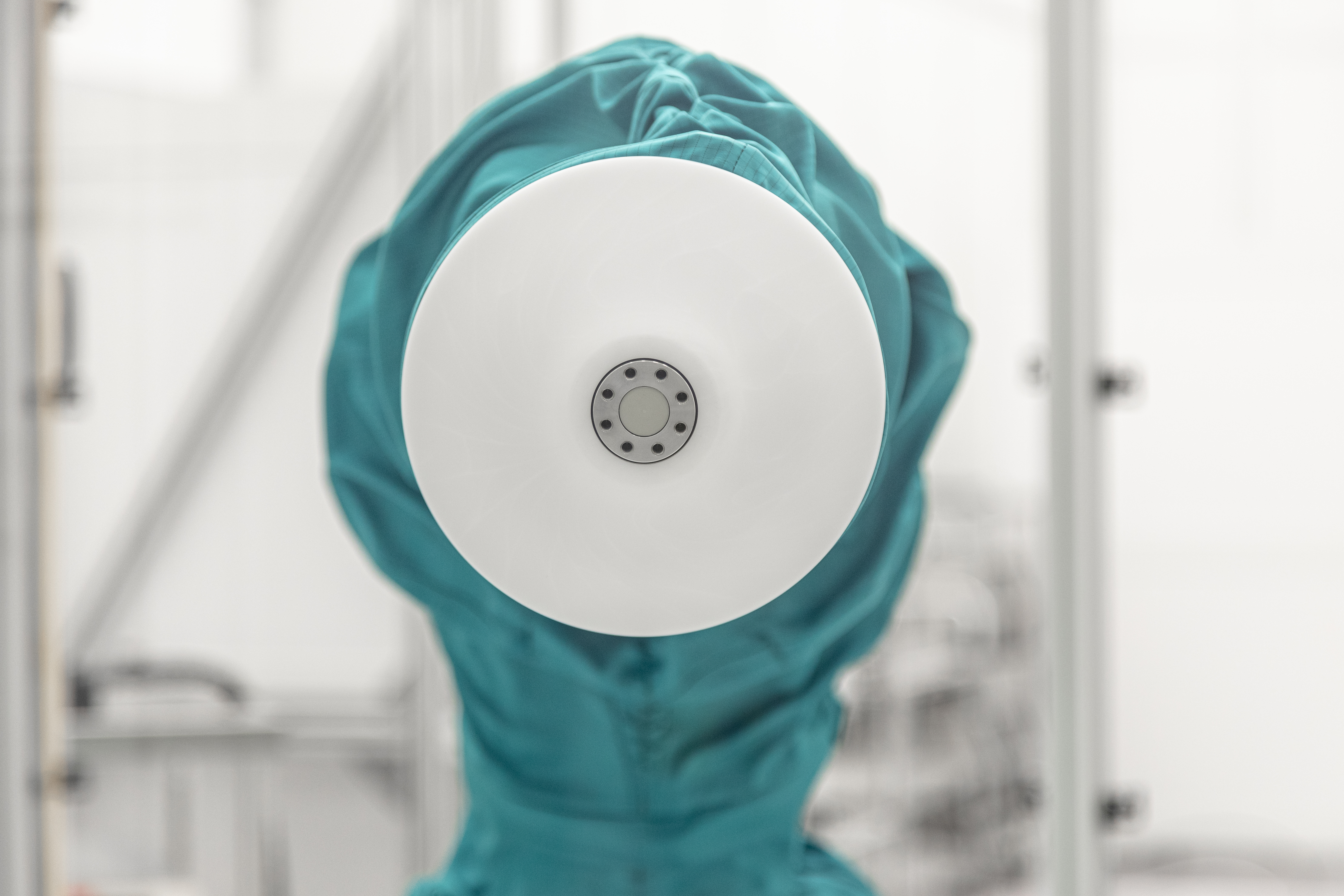

2ndSCIN® is a breathable, textile protective cover. It can be individually adapted to dynamic automation components. Inspired by the human skin, 2ndSCIN® is made of a permeable, flexible and multi-layered textile that creates a separation from the environment and thus a cleanliness barrier. The different textile layers are separated by means of spacers and can transport and discharge gases, moisture, substances and particles. Part of the protective technical skin are sensor networks that continuously collect data on particle contamination, chemical contamination, temperature and humidity. Using AI algorithms, this data can be evaluated and enables a predictive maintenance strategy. 2ndSCIN® is extremely quick to install and can be variably adapted to individual needs and requirements of producers and machines. In this way, it addresses requirements, that are not met by previous protective covers.

Industrial requirements

- Necessity of protective systems: no particles, lubricants, ACCs from the equipment or the protective technical skin

- Sensors for: Particle contamination (PAC), molecular/chemical contamination (MOC), temperature (T), humidity (h), air pressure (p), electrostatic discharge (ESD) Biocontamination, …

- Process safety with regard to contamination control

- Statements on the maintenance behaviour and maintenance strategy of the equipment

- Need for: flexible, modular, quickly feasible and powerful systems

Cleanliness specifications

- No contamination

- Cleanliness compatibility

- Mechanical properties (with regard to stability, tear resistance, elongation behaviour, electrostatic conductivity, cleanability)

- Sterilisability

2ndSCIN® – Enabler for cleanliness-critical automation technology

Product Video