LeanDA - AI-Based Process Transparency Using a Modular Sensor System

Tabbed contents

Expertise

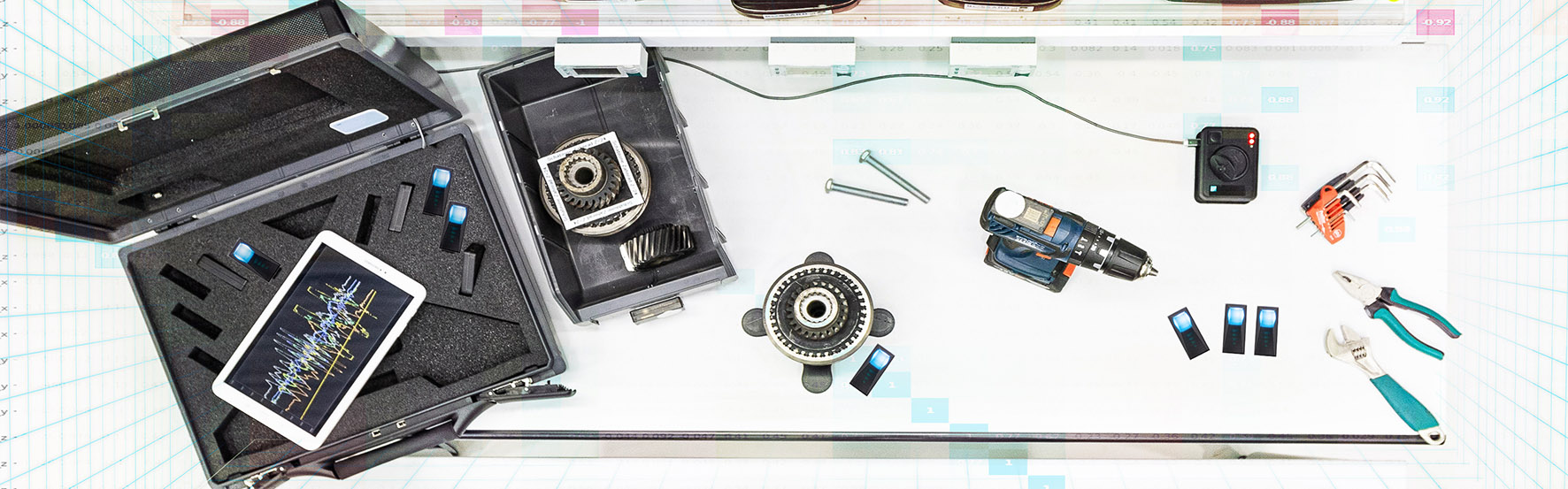

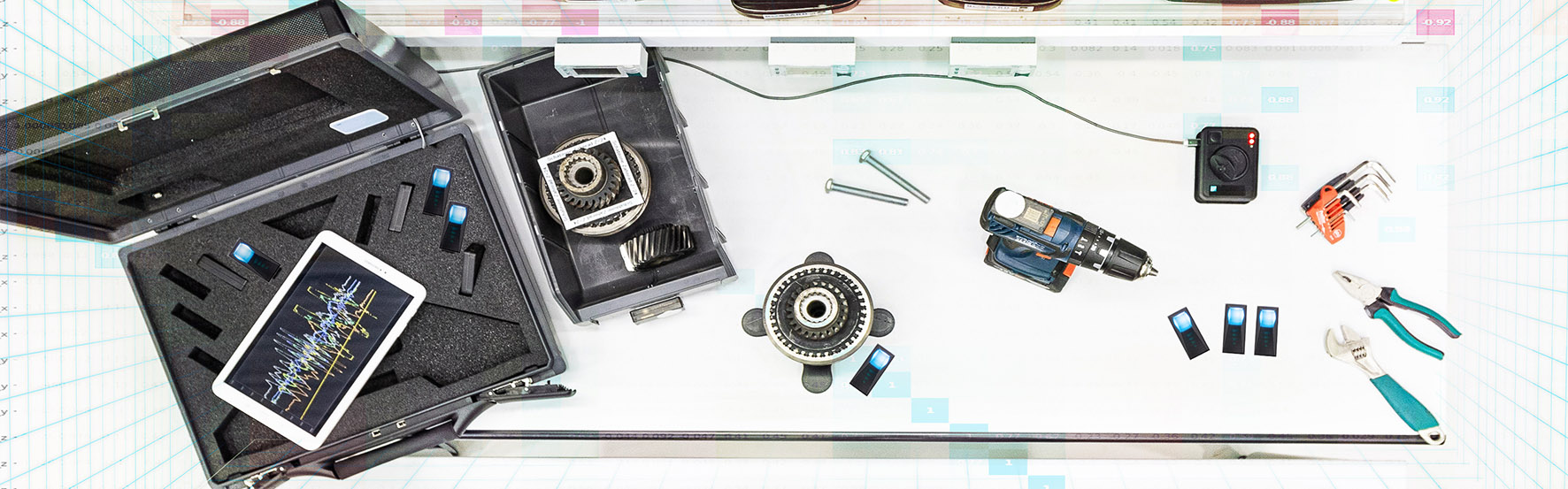

LeanDA (Lean Data Acquisition) is a Plug & Play process optimization toolkit developed at Fraunhofer IPA. By combining a modular sensor system with AI-based algorithms for process recognition, the toolkit makes manual and automated processes fully transparent and automatically reveals optimization potential.

LeanDA makes manual assembly processes transparent and is intuitive to use at the same time. The sensors can be attached to components, tools, fixtures and machines, for example, and can also be networked with additional data sources (e.g. ERP, MES systems, machine controllers, existing sensors) if required.

After a short training phase, the sensors transmit the assembly process data wirelessly to an edge device, which evaluates the data with the help of AI in near real-time: When did which process take place? When were there stoppages? Where exists potential for optimization?

LeanDA thus recognizes the process steps carried out and calculates the respective key performance indicators (KPIs). With this, we help process engineers identify waste in production processes and lay the foundation for value-added manufacturing.

Process data acquisition with LeanDA gives you the following advantages:

- Process transparency without a pre-existing tracking infrastructure, even in manual processes

- Automated and adaptable process recognition

- Detailed process evaluation through dashboard and key figures