Robot optimization

For production to run error-free and meet top quality requirements, high-precision robotic systems are essential. The various system components must interact perfectly. Unfortunately, in practice this is often not the case. Are your robots not yet functioning down to the finest detail? If so, we will be happy to assist you by measuring their accuracy or optimizing their performance. Thanks to high-quality measurement equipment and robotics expertise, we can pinpoint all sources of error and calibrate your robot components to a high accuracy. This enhances process quality and reliability.

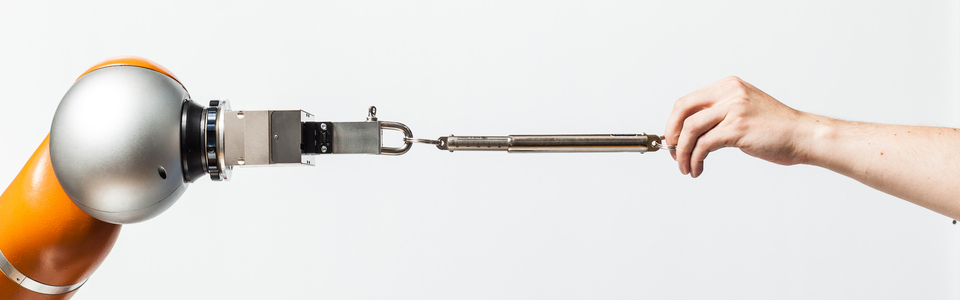

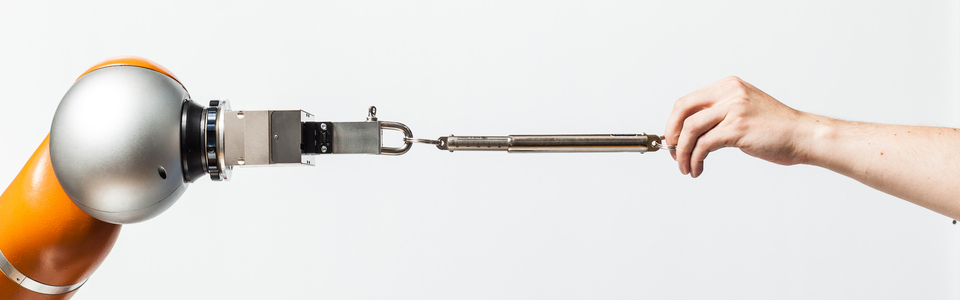

We are also experienced partners when it comes to the functional safety of your robot systems. Legal safety guidelines must be fulfilled while, at the same time, you need an application that meets your performance criteria, such as cycle time. Modern safety concepts allow man and machine to use the same workspace. Partial automation is often the key to success, particularly in cases where it is impossible to perfectly implement a purely manual or fully automated solution.

We are also happy to conduct market studies of any size for you on all technologies related to robotics and automation, and support you with benchmark activities. In addition, we can advise you on strategies for introducing emerging technologies into your company.

Measurement accuracy of robots and systems

Your needs

You need precise manipulation but currently have reliability problems or are unsure if your robot is calibrated accurately enough. Your processes are not being executed precisely or reliably enough and you do not know why. You want to improve absolute or repeat accuracy. We have already optimized many robots and systems. Take advantage of our knowledge and experience to help you solve your problem.

Our services

- Measurement of your robot cell and robot tools with our own measuring equipment and determination of exact parameter sets for calibrating cells and tools

- Calibration of integrated sensors: 3D, 2D or 1D measuring systems

- Measurement of absolute, repeat and trajectory accuracy of industrial robots using the Leica Absolute Lasertracker, which is capable of measuring positions at a sampling rate of 1000 Hertz and an accuracy of up to 15 µm

- Investigation of the impact of external influences on robot behavior, for example ambient temperature, excitation of the machine bed and the process steps performed

- Measurement of the thermal behavior of assemblies and automation components with a thermographic camera

- Measurement and calibration of gantry robots and special kinematics

- Design of calibration systems tailored to your application, e.g. deburring, milling, quality inspection and all high-accuracy and sensor-driven robotic processes

Reference

Safety

Your needs

You have questions concerning the functional safety of robot systems, be it about implementing a new application in compliance with standards, or about changes to an existing system. You would like to know more about the latest safety requirements, the state of the art, current research and the topics that are being discussed in national and international committees. So far, you have been unable to find a suitable testing facility for assessing the safety functions of your stationary or mobile robots. In short: You need to solve a safety challenge reliably and efficiently - with our experience, we are just the partner you are looking for.

Our services

- Information:

- Verification of standards and requirements

- Training programs

- Conception:

- Development of safety concepts

- Feasibility studies

- Implementation:

- Risk assessment support

- Practical tests

- Evaluation of safety concepts

- Supplier coordination

- Wide range of safety-related software tools to aid the implementation of safe robot systems

- Certification:

- Coordination with approval bodies

- CE marking support

Reference

More info ARAIG – Autonomous robots for assistive functions: basic interactive skills

More info Safe robot applications and cobots

- Information:

Performance optimization of robot systems

Your needs

Your application does not yet achieve the necessary availability or cycle times. You want to bring your hardware or software up to date. As an applied research institution, we always know about the latest technologies and integrate these into your application.

Our services

- Measurement and calibration of your system

- Determination and verification of performance values

- Compensation of capacity-related and spatial bottlenecks

- Recommendations for adapting (partially) automated processes to improve the workflow

- Advice on components designed or to be assembled in an “automation-friendly” manner

- Support in planning the refitting of existing systems

Reference

More about Planning Manufacturing Systems

Benchmarking technologies

Your needs

You want to identify the best technology providers in a particular field when it comes to specific performance criteria. It is important for you to know the advantages and disadvantages of certain competitor products and to obtain an unbiased assessment of them. As an independent research institution, we are your ideal partner.

Our services

- Advice and support for the implementation of benchmark activities

- Impartial assessment of competitors in a given market

Reference

More info OLP Study - Assessment of robot offline programming (OLP) systems

Market studies

Your needs

You are looking for comprehensive general or detailed knowledge about the robotics market or associated sub-markets. You would like to develop a new, promising product and know the prerequisites already today. Perhaps you would like or need to find out exactly where you stand in your industry. Join us in looking at the bigger picture and benefit from our general and detailed knowledge.

Our services

- Market studies of any scale on all technologies related to robotics and automation

- Surveys and interviews with experts

- In-depth overview of specific components and their classification according to certain criteria

Reference

More info Efficient innovative service robotics

Strategy consulting with in-depth technical support

Your needs

You have a long-term aim concerning robotics and automation and would like to achieve it with the help of an independent research partner. You need to set the right course for introducing future technologies today so that you can be at the forefront in a few years' time. Or would you even like to co-develop completely new technologies but need external resources to do this?

Our services

- Development partnerships individually tailored in terms of time and complexity, aimed at planning and implementing fundamental innovations in your company

- Shaping tomorrow today with the aid of research results that can be geared directly to your practical needs

Reference

More info Sheet metal processing of the future

Kinematics development

Your needs

You would like to modify your robot systems with regard to freedom of movement, motion dynamics, working space or accessibility for your application. To ensure the functionality of your systems, their kinematic configuration must be optimized. We have already implemented a wide variety of robot systems in challenging applications - and can also identify exactly what you need.

Our services

- Preliminary tests to ascertain the kinematics configured for your robot system

- Integration of sensor technology to optimize the kinematics

- Development of kinematic models to improve motion sequences

- Design, development and implementation of measures to optimize motion sequences for new or existing robot systems

Reference

More info Cable-driven parallel robots