Factory Planning and Intralogistics

Are you considering reorganizing your factory to make it fit for the future? Do you want transparency instead of complex structures that have become established over the years? Has your material flow become very complex over time? Do your production processes involve long distances and high complexity? Or do you want to expand your factory and take the opportunity to restructure your plants at the same time? Do you want to build a new factory and need expert knowledge from a partner with a wealth of planning experience? Are you thinking about integrating another site into your production network or transferring parts of your operations to a new location? Is cost pressure becoming an issue in your production but you are unsure how to cut costs effectively?

We offer you replanning or development planning, expansion planning or restructuring of complete factories, selected production areas or individual production lines. We analyze your production and uncover waste and optimization potential. In factory design, we support you in the conception of a lean, changeable and people-oriented factory and accompany you through to the realization of the finished factory. Together in an integrated project team with your experts and ours, we develop individual, customized solutions.

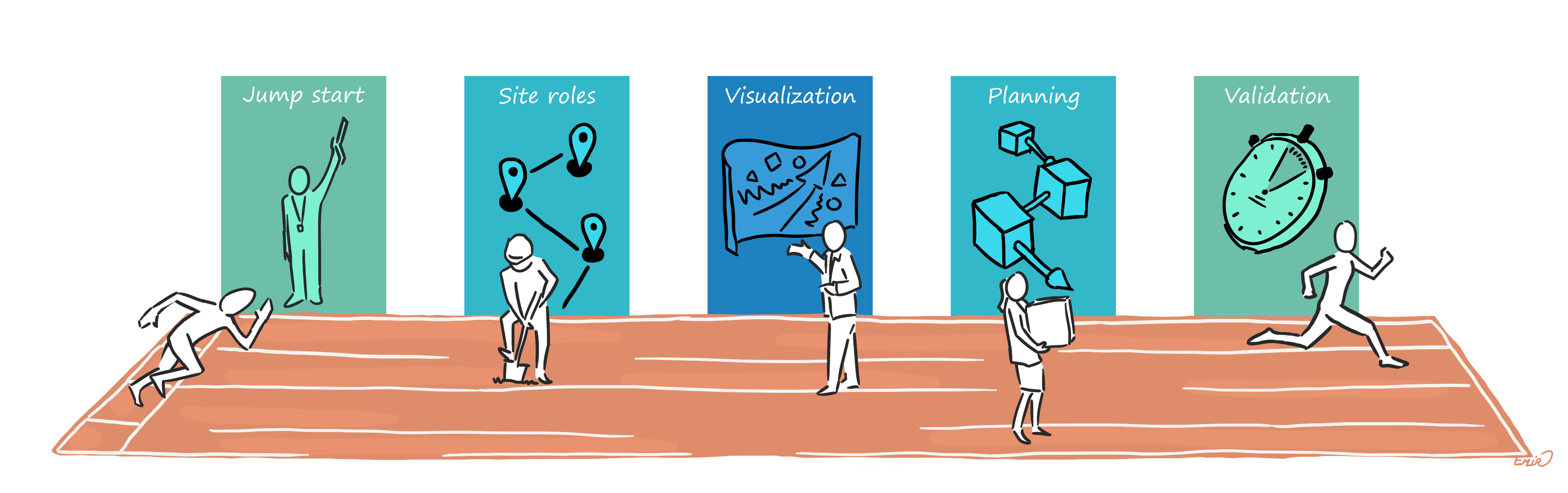

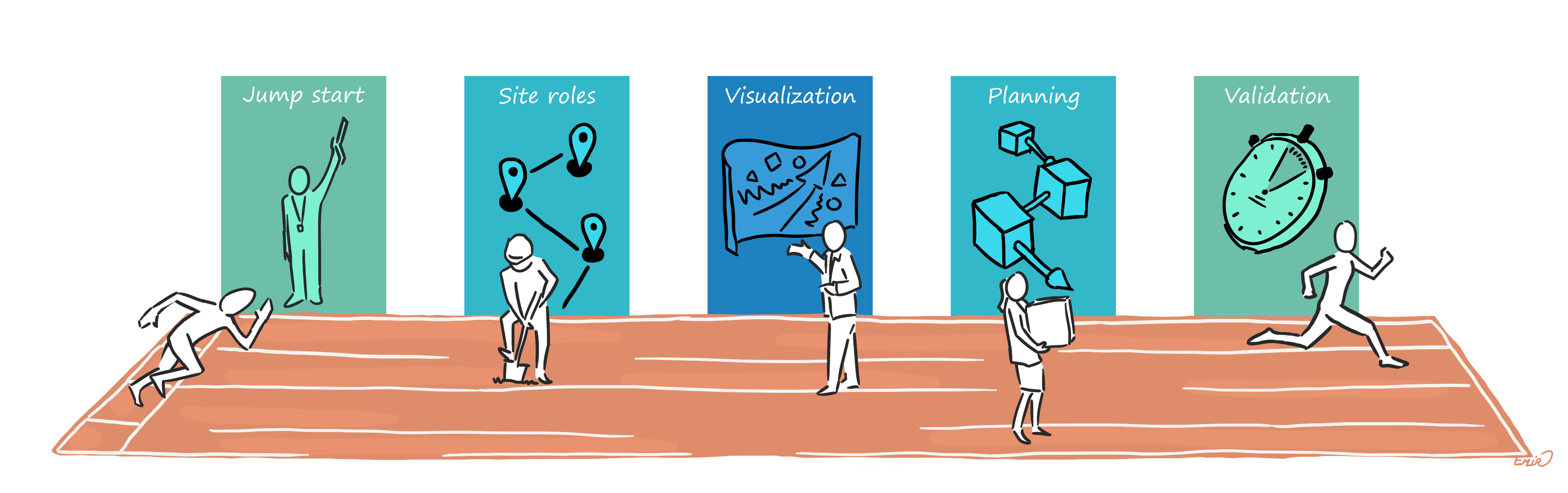

You are still undecided about the right approach for your factory planning project? In a joint jump-start workshop, the experienced experts at Fraunhofer IPA will give you an introduction to the planning procedure of VDI Guideline 5200 "Factory Planning", for which we were in charge. You will get to know our methods, which have been proven in a large number of projects across all industries, and which are necessary to achieve planning reliability. We coordinate the task description with you and determine the ideal planning team together. So you can start planning optimally prepared.

We are pleased to support you in your factory planning project in the following areas: