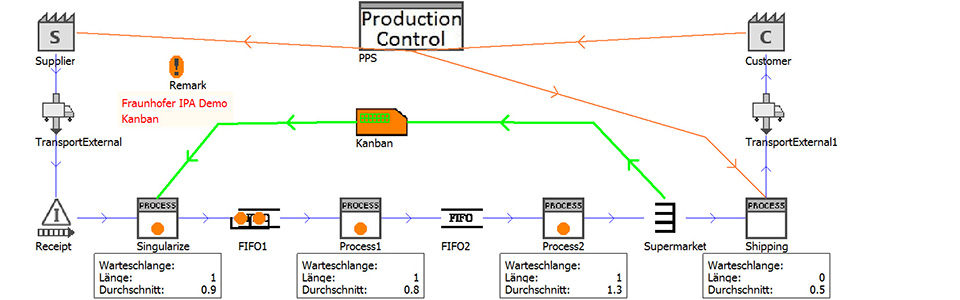

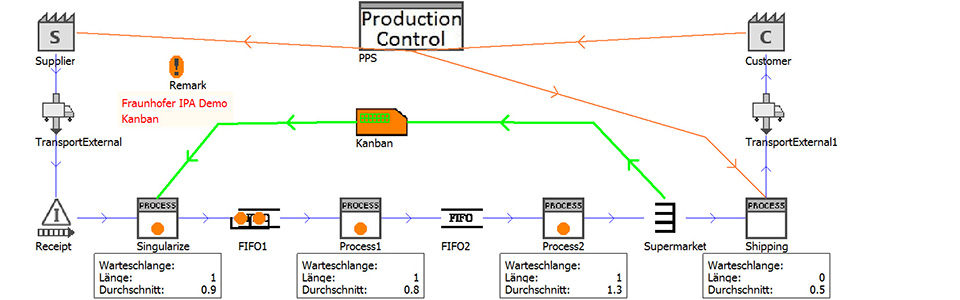

Value Stream Simulation

Simulations can be carried out to validate the results of value stream mapping and design. Based on the KPI system of the value stream method, the optimized material flow as well as the new control concept with all its parameters integrated into the design is modeled and validated for specific issues. Especially in the case of highly-dynamic complex productions, simulation increases planning reliability in the production process.

Value stream simulation supports production planning in the following ways:

- Quantitative assessment of savings potentials

- Assured adherence to schedules

- Prediction of fluctuations in throughput times and improved organization of rolling stocks and stocks of finished products

- Evaluation of material flows and production control to assess robustness in the event of stochastic flows (e.g. machine downtimes)

- Parameter optimization, such as batch sizes, re-supply quantities, order sequences, etc.

- Comparison of different solution options obtained from value stream mapping and design