Services and expertise

Robots, intelligent machines, and automation solutions aid both industry and service providers in the professional and private sector. They are used wherever tasks are monotonous, dangerous, expensive, or unpleasant and arduous for humans. In addition, they can help us in everyday life by assisting with common household tasks or providing communication and interaction options. Thanks to digitization, improved algorithms, new sensors and networking options, robot technologies are constantly being optimized to make them even safer and more efficient.

Fraunhofer IPA offers solutions ranging from strategy development through software and hardware development to final system integration. In short, we help with everything it takes to make the best possible use of robots for your specific challenge.

Automotive

The automotive industry has been an innovator and driver of automated production processes for decades. Many systems and technologies became established here for the first time and were subsequently able to establish themselves in other industries as well. Robot applications for the automotive industry are therefore a focus of research at Fraunhofer IPA.

In the research area of networked production, we develop cyber-physical manufacturing systems and reconfiguration solutions, adaptable automotive production, e.g., using mobile robots or human-robot collaboration solutions. Together with industry and research partners, we are working on technologies for the automotive production of the future in the "ARENA2036" research factory.

- More about "automotive" at Fraunhofer IPA

- More about our work on the "ARENA2036" research campus

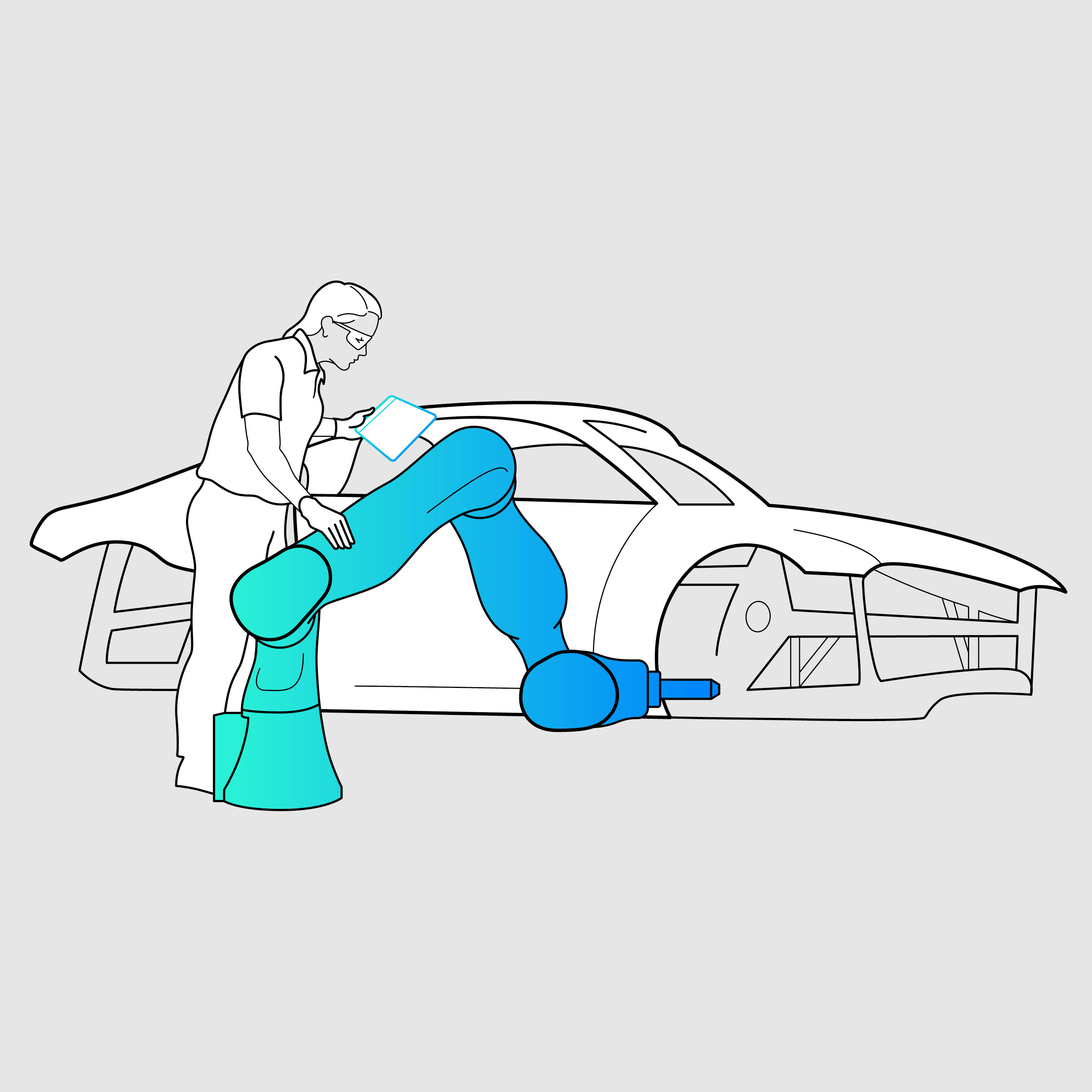

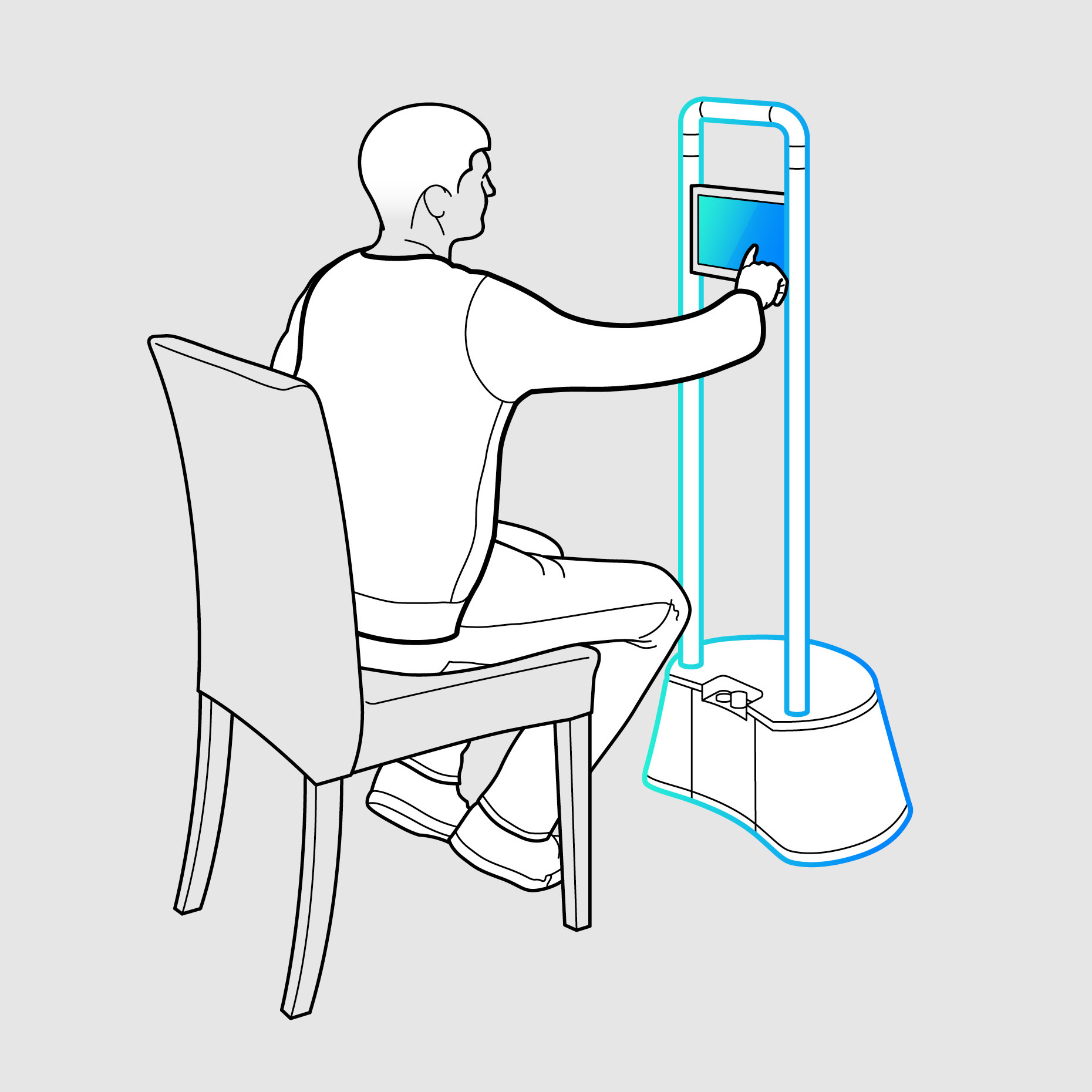

Healthcare

Robot technologies can assist and relieve staff in clinics and care facilities and thus contribute to better care for patients and residents. For instance, stationary robotic arms are used in the operating room or for diagnosis. Mobile robots can be used for transport and cleaning tasks, as intelligent care aids, or for direct interaction with people in need of care in the context of therapeutic or activation functions.

- More about "service robots for assisting with care tasks in nursing homes and hospitals"

- More about "innovative technologies for robotic use in the operating room" and the "automation in medicine and biotechnology" project group

- More about "biomedical measurement and sensor technology"

- More about the underlying "service robot technologies"

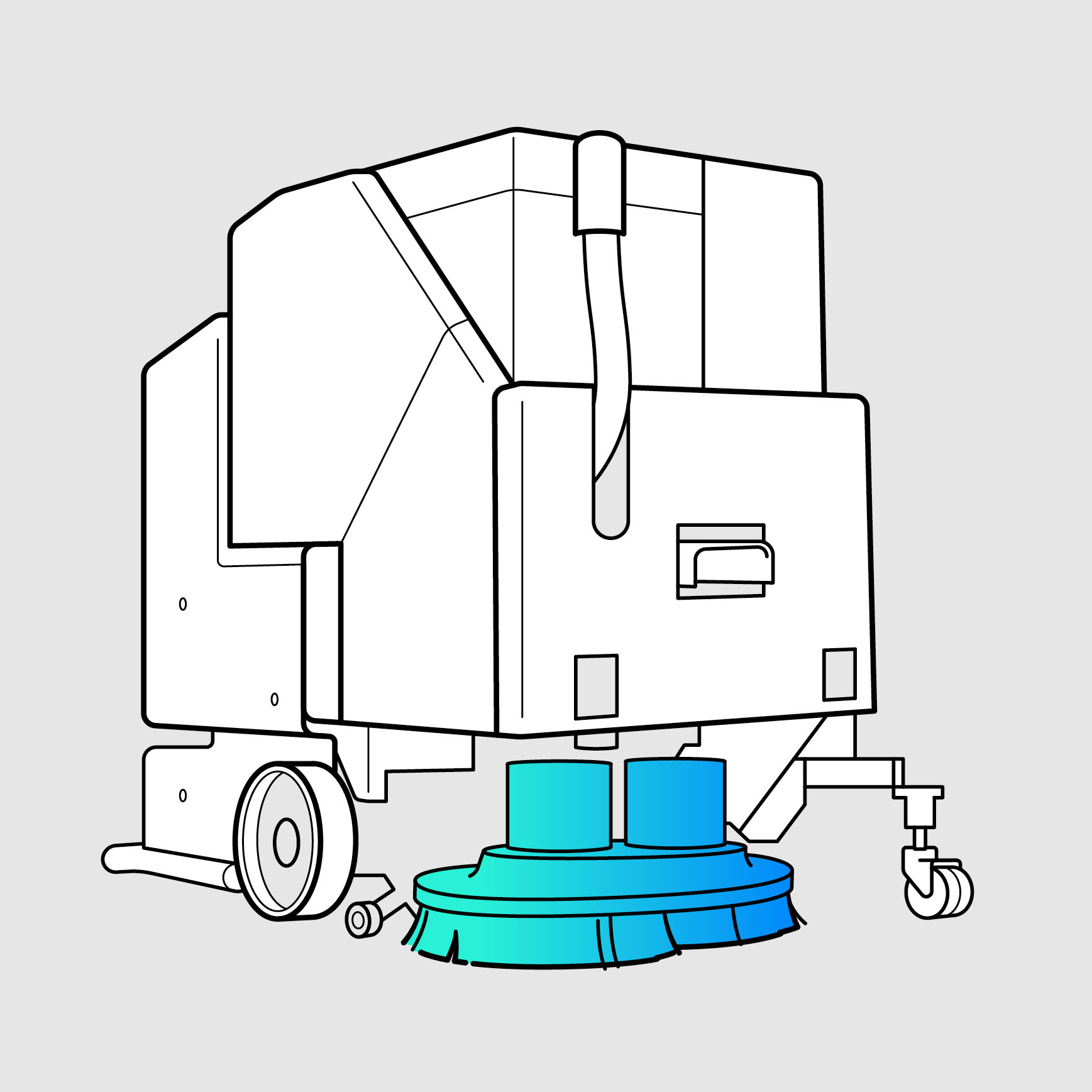

Industrial Cleaning Robotics

Cleaning robots offer the potential to automate routine tasks such as regular floor cleaning or simple handling functions, thus relieving increasingly scarce staff. Disinfection robots can counteract challenges such as those posed by the Corona pandemic. The autonomy and associated efficiency of the robots when used in public spaces play a particularly important role for economic deployment.

- More about "cleaning and disinfection robots"

- More about the underlying "service robot technologies"

Household Robotics

In addition to the already established applications such as vacuum cleaning and lawn mowing robots, an increasing number of service robots help the elderly or other people in need of care to maintain their independence. To do this, the robots must be easy and intuitive to operate, able to reliably detect users and their surroundings visually, and operate safely and autonomously in this dynamic environment.

- More about "assistive robots"

- The "Care-O-bot®" product vision – now available in its fourth generation – serves as a powerful development platform for applications in this field of use.

- More about "household robots with a focus on cleaning robots in private environments"

- More about "entertainment robots"

- More about the underlying "service robot technologies"

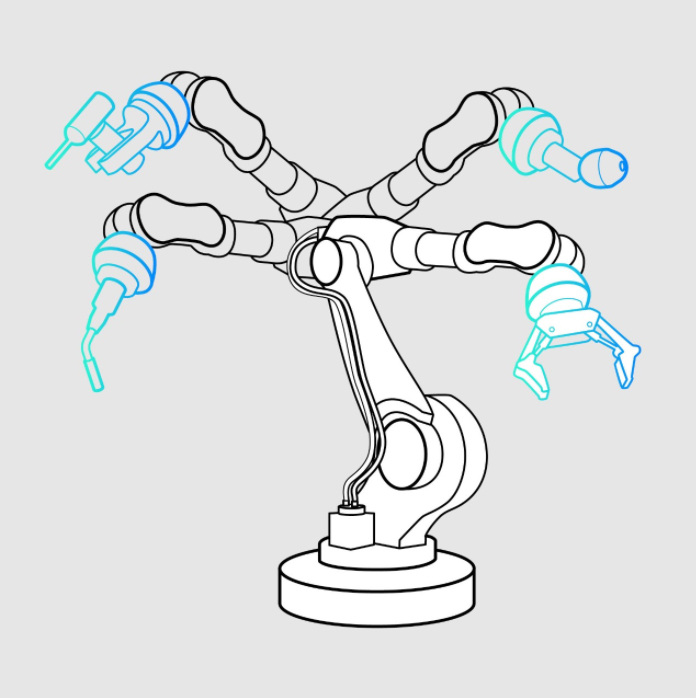

Industrial Robotics

Due to their mechanical flexibility, payload capacity, precision, and repeatability, robots offer enormous opportunities to make productions more efficient. At the same time, the associated software is getting better and better – and more user-friendly. To the corresponding research areas and services offered by Fraunhofer IPA:

We help to meet high process requirements for (partially) automated assembly with the aid of robots.

- More about "assembly automation"

- More about "pitasc" software kit for force-controlled assembly processes

- More about "robot-based drilling and riveting" (in German)

- More about "(dis)assembly of battery modules"

- More about "bonding – sealing – contacting"

Highly accurate calibrated systems and simple and flexible programming are particularly important here:

- More about robotic "welding and machining"

Not mountains but moving objects: we have the right gripping planning toolbox for any application. Under the term AI Picking, we offer a variety of smart handling solutions, such as the industry-proven bp3™ bin-picking system, AI-based model-free, model-based and hybrid gripping planning solutions for industrial and service robotics applications, AI-based object recognition and position estimation methods, intelligent methods for packing (bin packing) and palletizing, as well as specialized AI techniques, such as for segmenting packing materials or resolving object entanglements during gripping.

- More about "handling" and material flow, including separation and gripping systems for production, intralogistics and more.

- More about "separation processes using robots (bin picking)"

- More about "Deep Picking"

- More about "activities of the Center for Cyber Cognitive Intelligence and robomotion GmbH" (in German)

- More about the Fraunhofer IPA "Bin Picking" dataset and challenge

- More about the automation of "goods and retail logistics"

- More about the development and customization of "gripper systems"

- More about handling with "service robots"

- More about the mobile lab robot "Kevin"

- More about "bioinspired effectors"

When applying paints, consistency and precision are paramount:

- More about "automated painting"

- More about "overspray-free coating with the MikroCoat process"

- More about the fully automated "SelfPaint" painting cell

- More about the underlying "application technology"

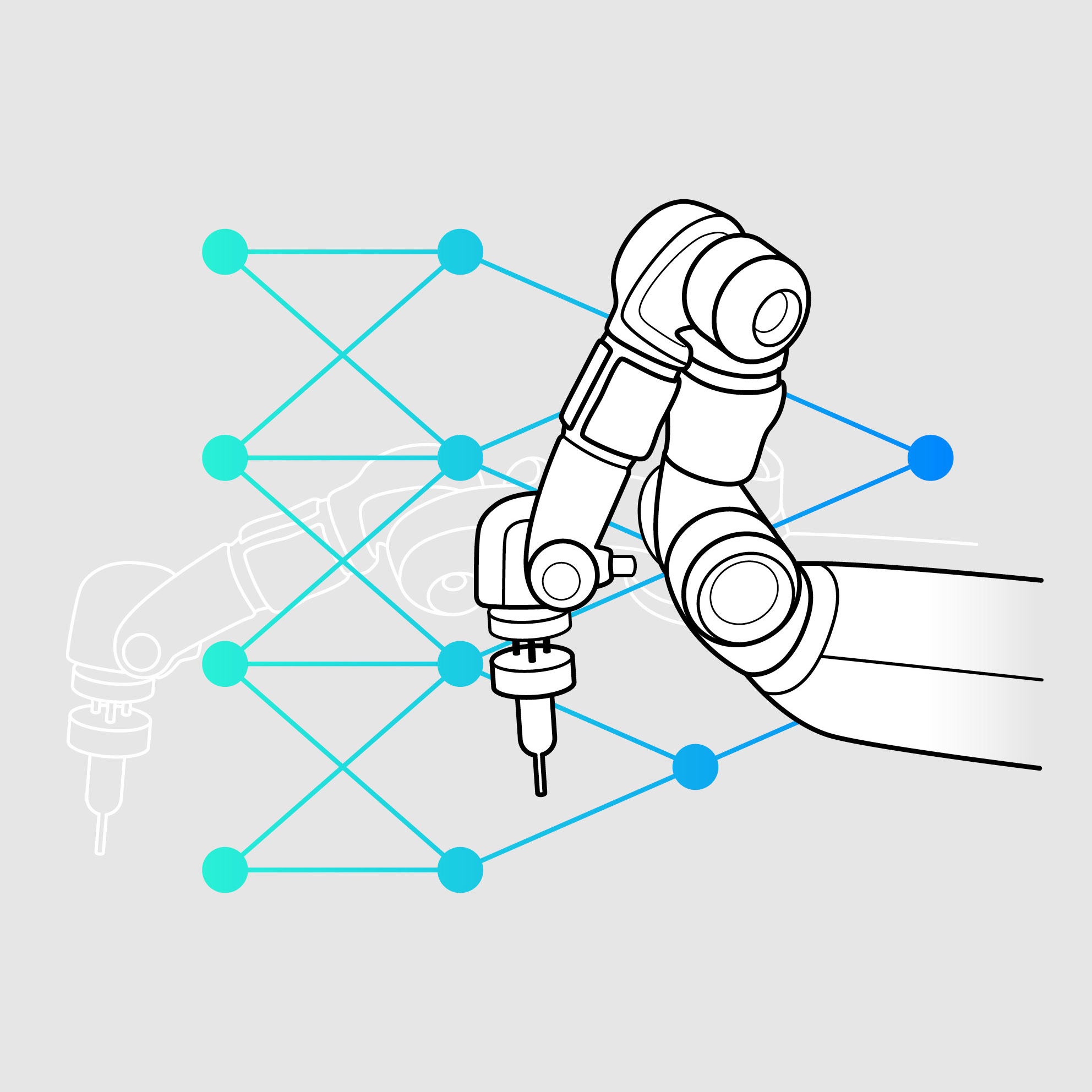

Artificial Intelligence

Artificial intelligence (AI) and particularly machine learning (ML) enable autonomous intelligent learning to advance robotic applications that were previously not economical to automate due to their diversity of variants. In the long term, our goal is to develop an ecosystem in which robots can program and organize themselves via digital twins of the manufacturing environment on the one hand and the real manufacturing environment on the other.

To use AI for robot applications, we develop solutions regarding topics such as object recognition, material flow, or networking mobile robots. In the Center for Cognitive Robotics, together with companies we are researching into ways for robots to be given cognitive, i.e. perceptual, capabilities in order to provide more efficient support in industry and the service sector.

- More about the "Center for Cognitive Robotics" and your participation opportunities

- More about the robotic application areas of AI

- More about "separation processes using robots (bin picking)"

- More about "3D image processing"

- More about "automatic component analysis with NeuroCAD"

- More about the "Rob-aKademI" project

- More about "camera-based scene analysis"

- More about the "Center for Cyber Cognitive Intelligence CCI" (in German)

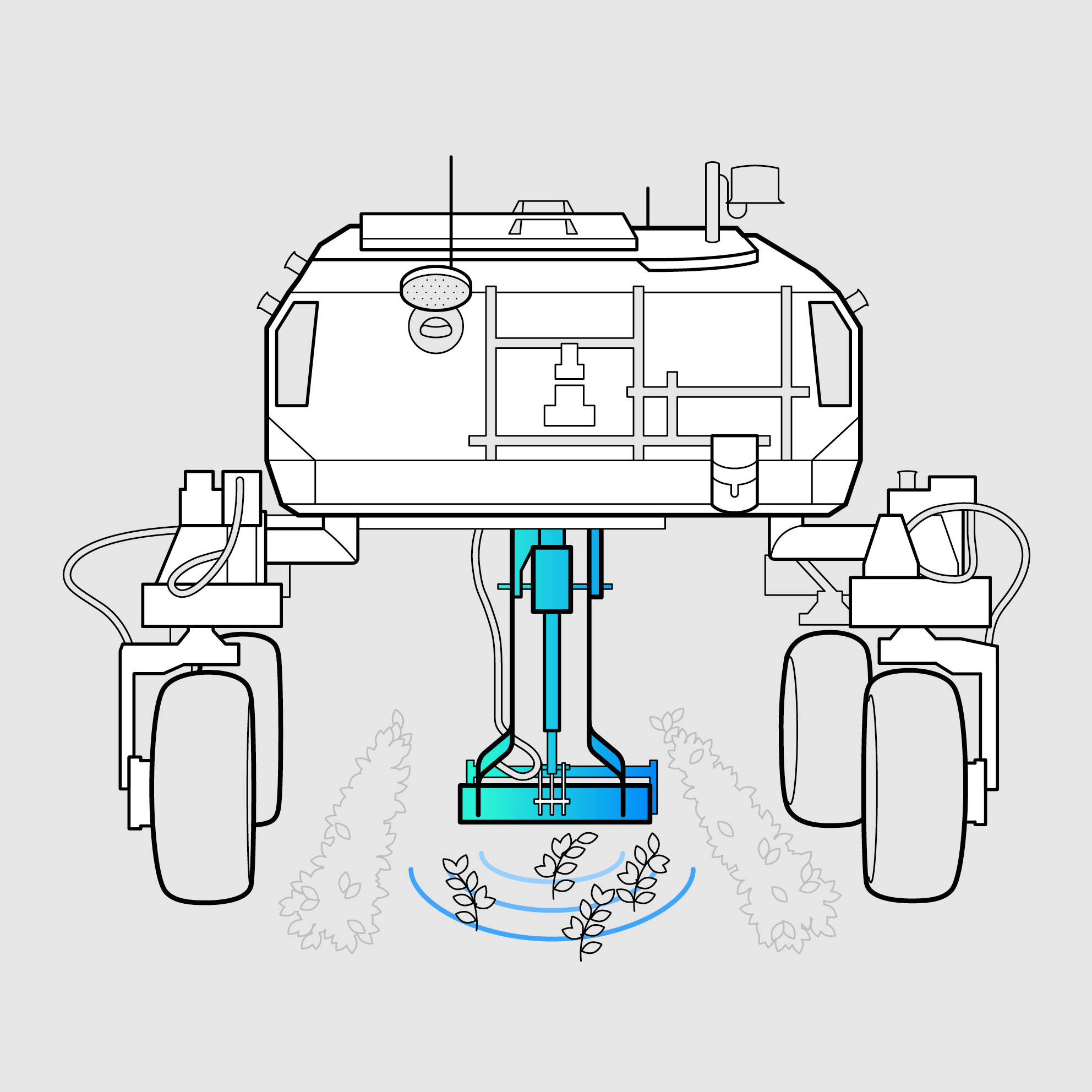

Agriculture

Agriculture is already highly technologized and the step from semi-autonomous, data-based applications to robotics is often clear. Autonomous field robots can take over work related to crop protection, improving the farmer’s crop and soil information through targeted data collection. Intelligent, decision-making, and plant-specific applications can increasingly reduce or completely substitute chemical crop protection measures to better protect the surrounding flora and fauna and produce higher-quality products. We are researching into this, for example, together with seven other Fraunhofer institutes in the lead project "Cognitive Agriculture".

- More about "agricultural robots"

- More about the lead project "Cognitive Agriculture"

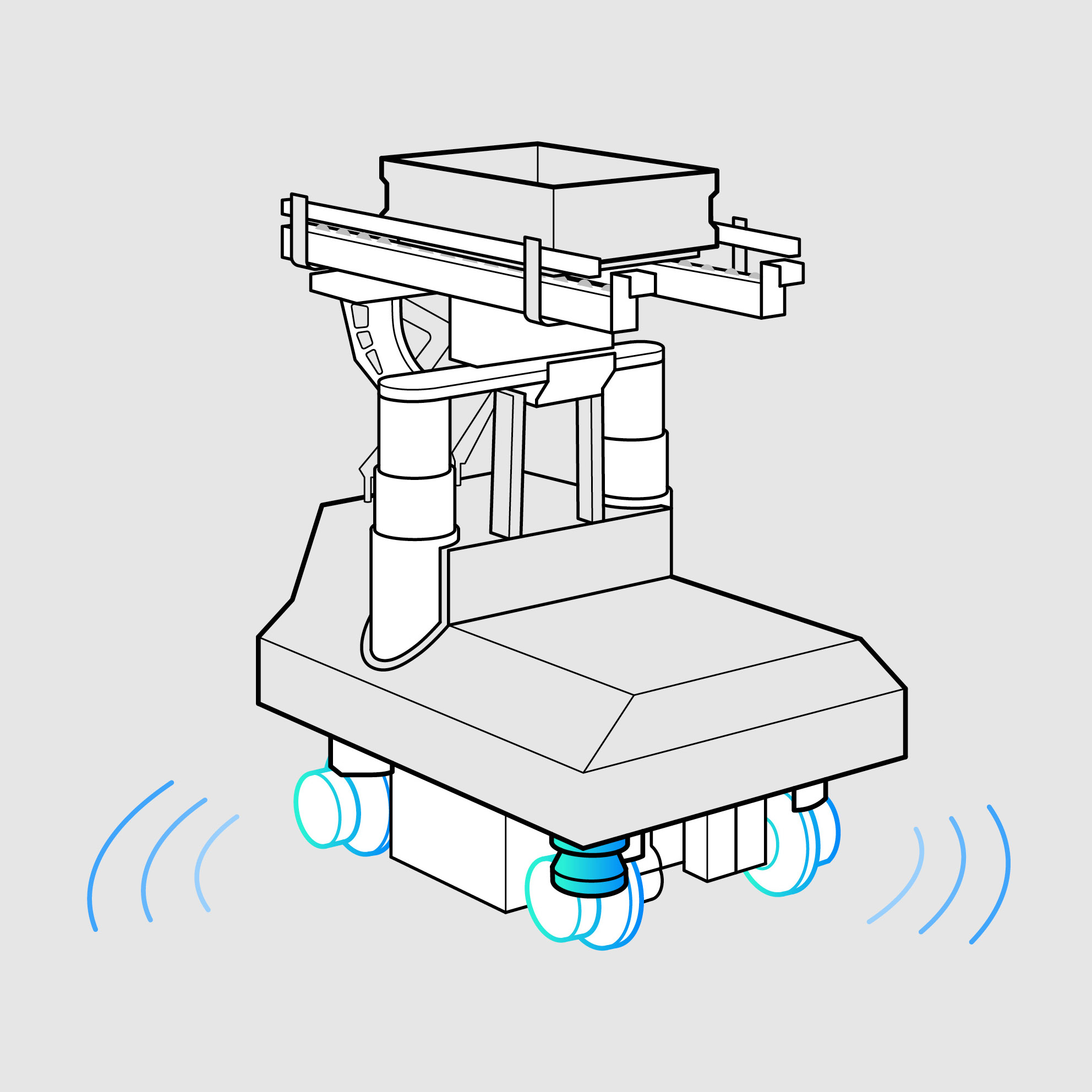

Logistics

Large order quantities, prompt deliveries, or even fast transport for efficient production chains: automation in logistics is booming and enables goods or components to be delivered efficiently in the right place at the right time. Smart products, containers, or conveyor systems that can communicate and interact with each other, as well as with employees, are essential to the development of autonomous and versatile intralogistics systems.

The automation solutions in demand include, for example, picking up, transporting, or even packing goods. The key technologies: autonomous navigation, (mobile) manipulation, 3D image processing and safe human-robot interaction.

At "Werk 150" in Reutlingen, the transformation to smart logistics is being researched and demonstrated using, among other things, assistance robots and automated guided vehicles.

- More about "Werk 150" and "data-based production and logistics management" (in german)

- More about the automation of "goods and retail logistics"

- More about "Automated guided vehicles (AGVs)"

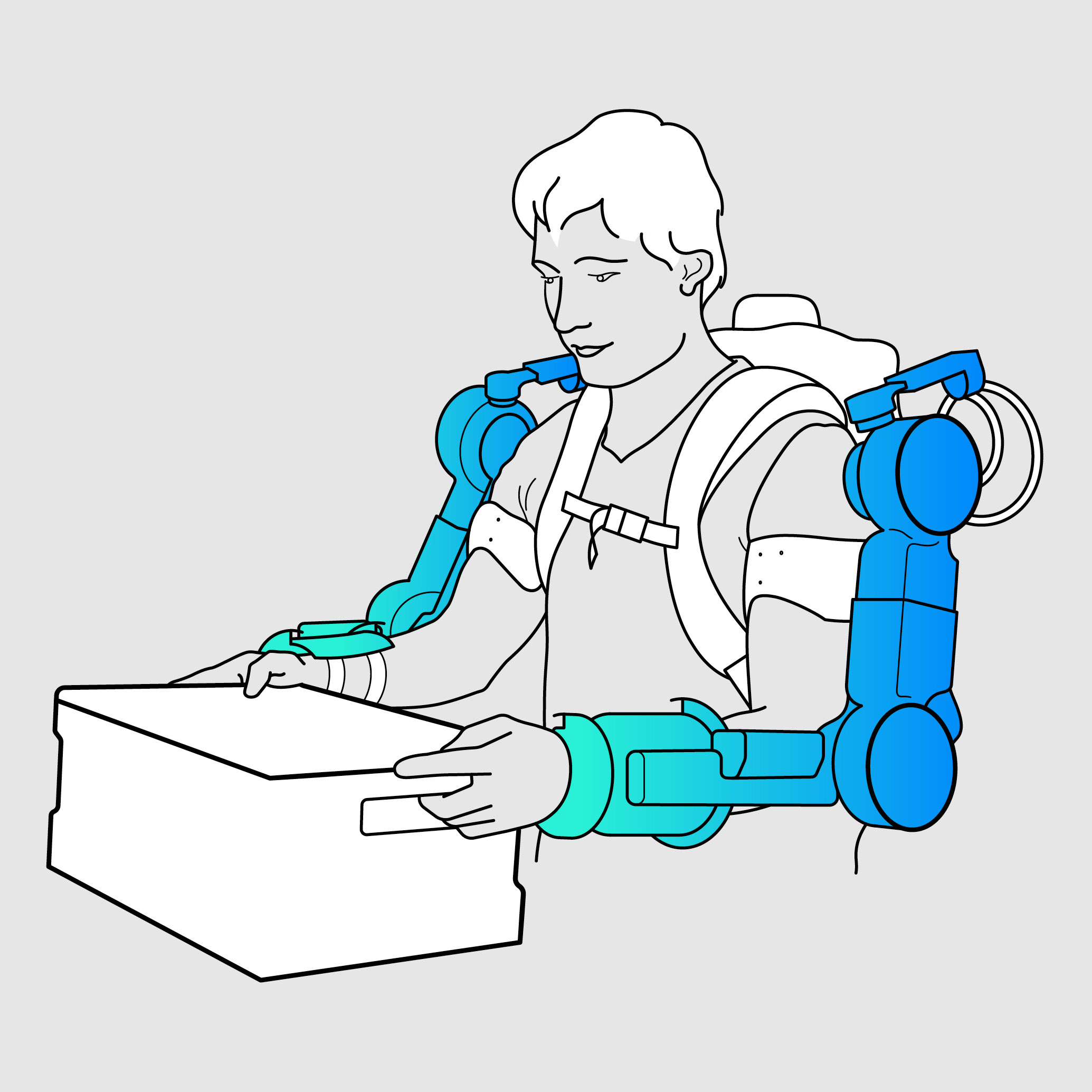

Human-Robot Cooperation and Biomechatronic Systems

Over the years, humans and robots have increasingly become a team. While the classic industrial robot must work safely enclosed away from humans, the numerous models of lightweight robots and new safety technologies, for example in sensorics, offer the possibility of robots and humans working in parallel or even together in the same workspace. We work with you to develop the application with human-robot cooperation that is right for you and provide you with comprehensive advice on all questions relating to safety and cost-effectiveness.

Humans and robots become an even closer team when it comes to body-worn systems: prostheses, orthoses, or exoskeletons can maintain, increase, or restore mobility. In addition to healthcare, our applications are also specialized for use in industry. Non-ergonomic working conditions, such as repeatedly lifting heavy objects, often lead to musculoskeletal disorders. To prevent these, biomechanical systems can provide workers performing heavy physical work with mechanical support. One of our solutions is the Stuttgart Exo-Jacket technology platform. The modular exoskeleton, which supports the upper extremities, is currently designed for handling processes in logistics. In the future, it will be able to automatically recognize what the user wants to do based on bio signals.

- More about "Motion control Systems"

- More about "Exoskeleton"

- More about "safe human robot collaboration with assistive robots"

- More about "safe-human-robot-interaction"

- More about "intelligent surfaces for human-machine interaction"

- More about "sensor mat for standing workplaces"

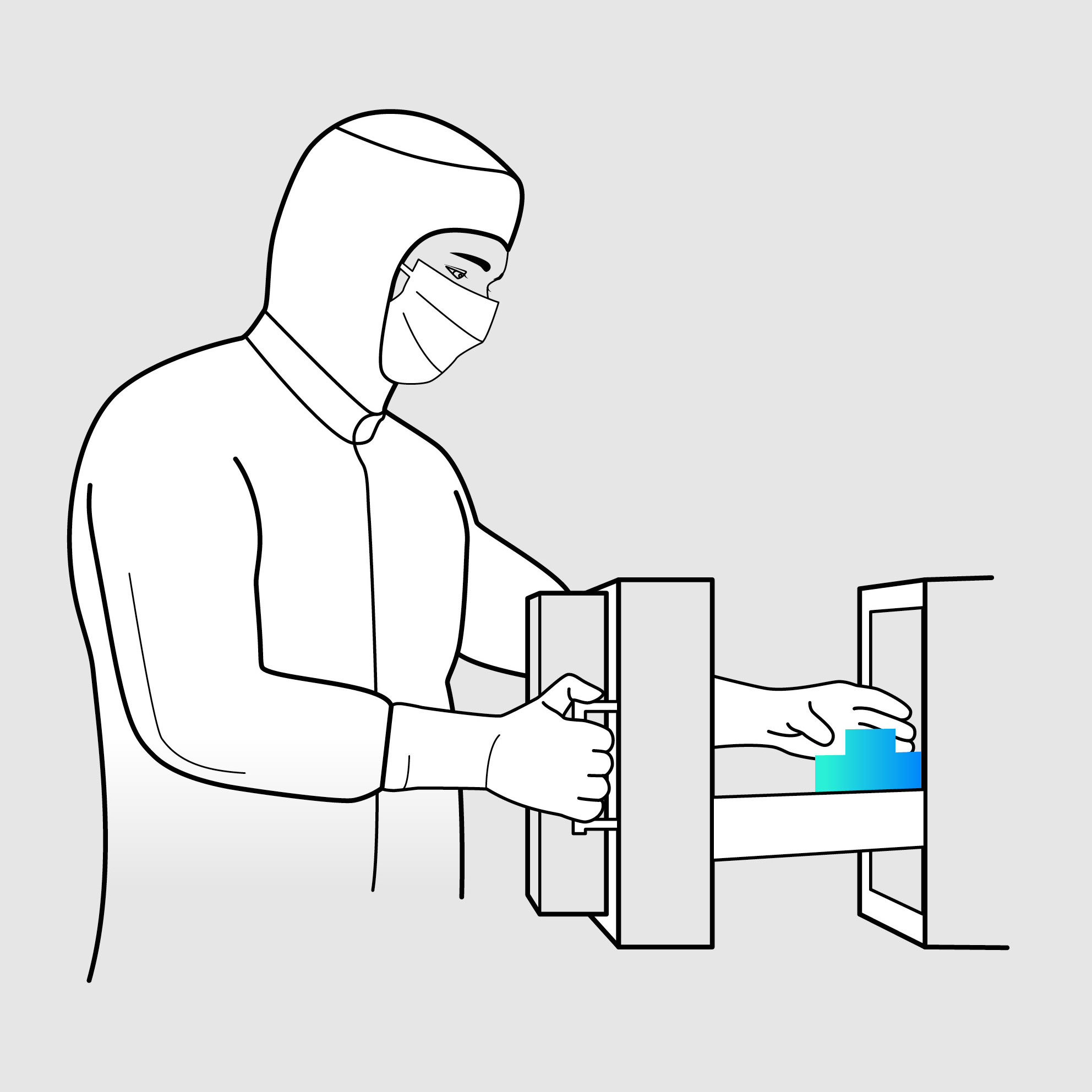

Cleanroom

In hygienically critical manufacturing environments, preventing microbial and particulate contamination of the end product is key. The selection of suitable materials and the geometric design of equipment have a decisive influence on their suitability for use in clean environments.

Our "2ndSCIN®" development is a system for upgrading production facilities that are not specifically designed for cleanliness-critical processes. The customized, flexible enclosure is created using layers of fabric through which air can flow and guarantees the highest level of cleanliness suitability. Integrated sensor networks allow AI-based monitoring for the continuous assessment of conditions.

To ensure sufficiently clean production areas, it is particularly important to make an objective, practicable, and meaningful evaluation of the cleanliness-relevant properties of all cleanroom components, equipment, and consumables. Within the scope of "TESTED DEVICE®", manufacturing equipment such as robots are tested and certified for their cleanliness and cleanroom suitability.

- More about "cleanliness-suitable equipment and components"

- More about "2ndSCIN®"

- More about "cleanroom certification"